6 m Dual Column Outrigger Aluminum Platform Aerial Work For Sale

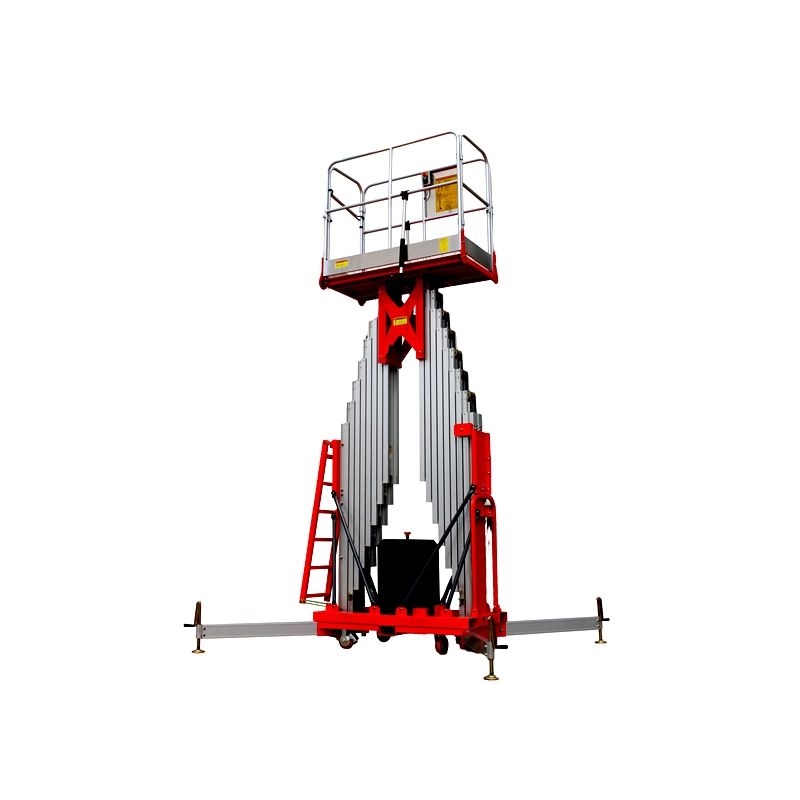

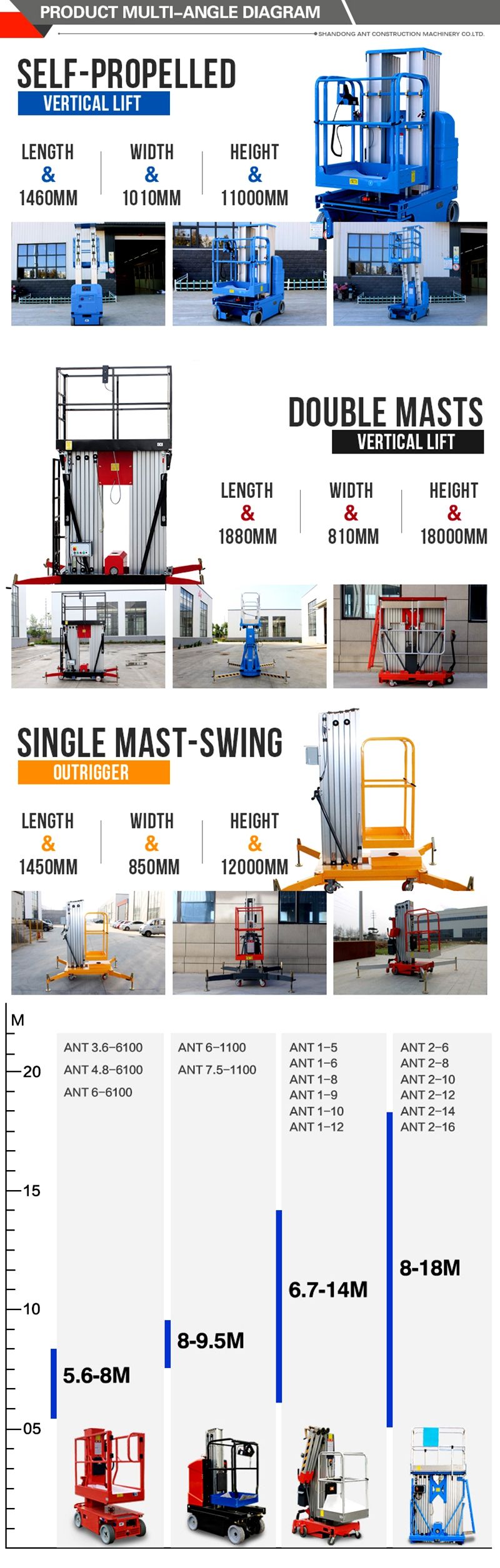

ATWY2-6 Dual-Column Outrigger Mobile Aluminum Platform: Efficient and Stable Solution for 6m Two-Person Aerial Work

Dual-Column Outrigger High-Strength Architecture: Double Breakthrough in Load Capacity and Stability

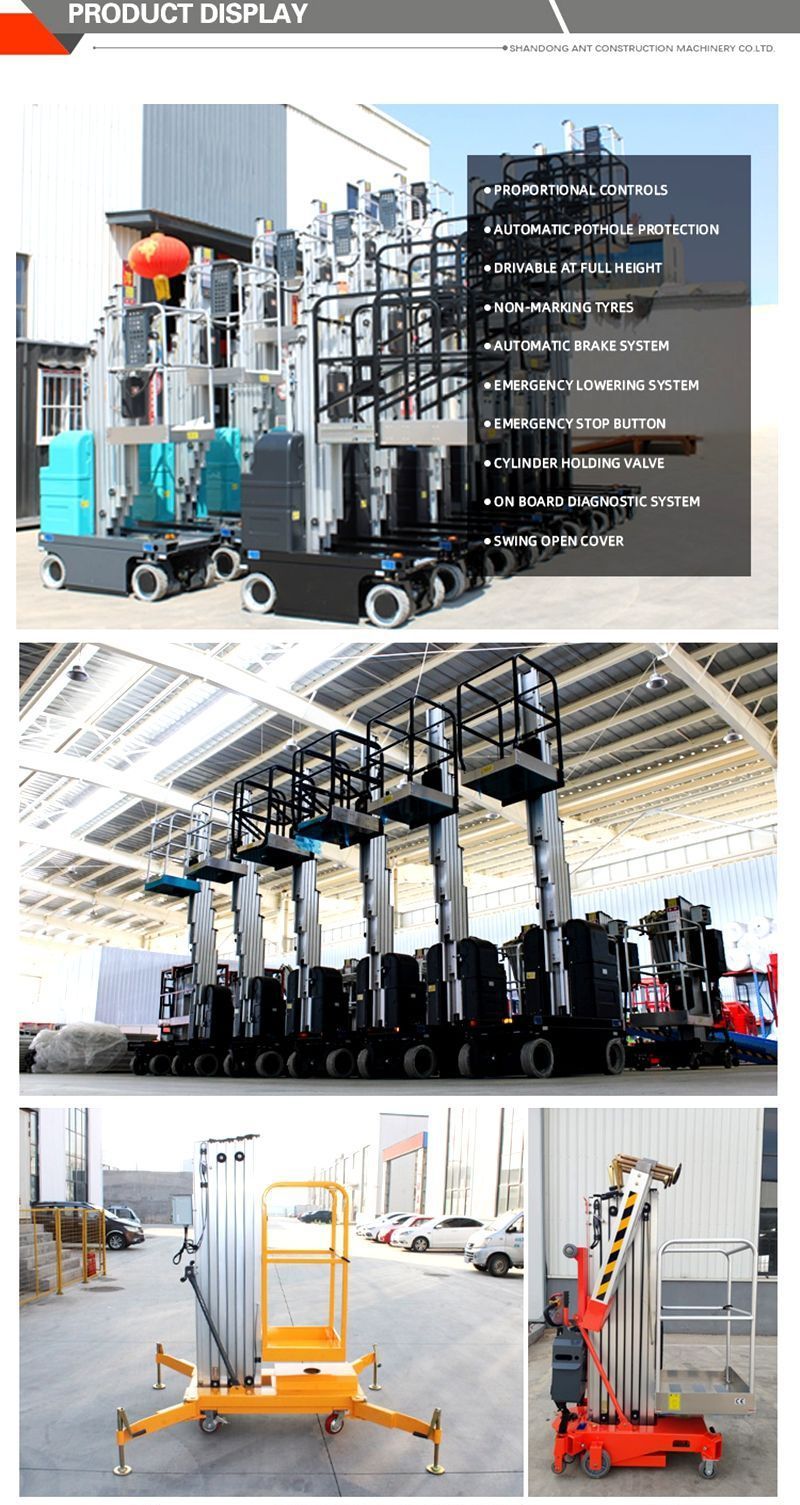

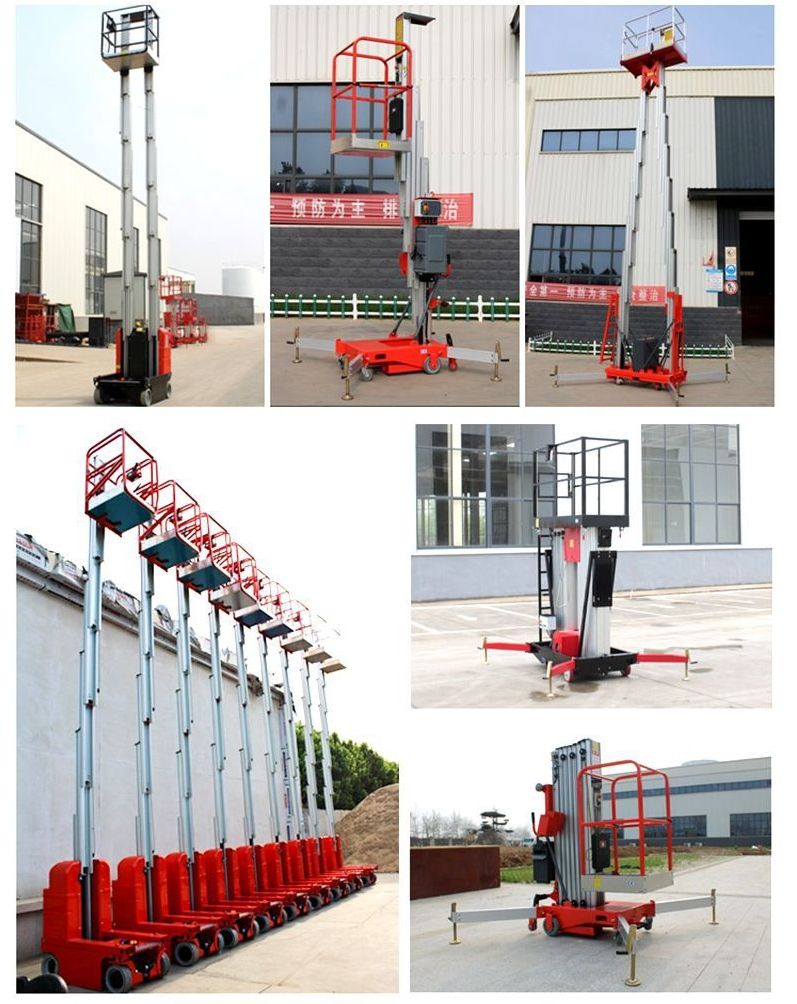

The ATWY2-6 features a dual-column parallel aluminum alloy structure, increasing the anti-tip moment by 40% compared to single-column designs. It achieves an 8m maximum working height and 6m platform height, supporting 2-person collaborative operations with a 250kg rated load. The widened 1.45m × 0.7m work platform offers 110% more area than single-column models, adapting to tool placement and collaborative operations for two persons. The retracted body dimensions are 1.48m (L) × 0.81m (W) × 1.99m (H), allowing passage through ≥0.9m-wide corridors and standard freight elevators (car size ≥1.5m × 1.1m). The deployed 2.1m × 1.7m outrigger coverage forms a stable quadrilateral support via cross-braced structure, with platform sway ≤12mm under 250kg load—suitable for fine-operation two-person tasks like electromechanical installation and decoration.

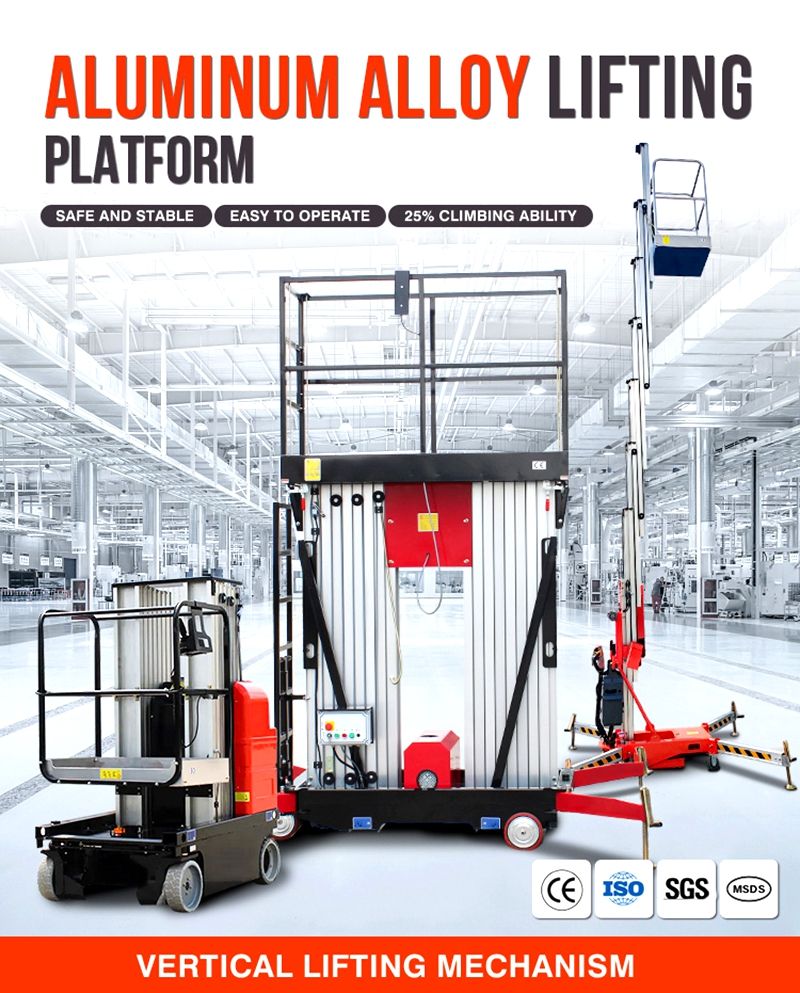

Dual-Power Co-Drive System: Full-Scene Energy Adaptation

The platform integrates AC/DC dual-power modules for flexible switching in different environments:

Industrial-Grade AC System: Compatible with 380V/220V/110V three-phase/single-phase power, a 1.5kW motor with synchronous belt drive achieves 0.6m/s smooth lifting speed. Ideal for continuous operations like factory production line maintenance and logistics warehouse two-person high-bay racking, it runs 24/7 when plugged in.

DC Power System (Optional): Powered by two 12V batteries in series, a 1.6kW DC motor drives the hydraulic pump station, supporting 4 hours of continuous operation (10 lifting cycles/hour at full charge). The 12V/15A charger completes a full charge in 6 hours, suitable for outdoor municipal streetlight maintenance and construction site temporary lifting—free from cable constraints for mobile work.

The hydraulic system uses dual-cylinder synchronous lifting technology, intelligently matching lifting/descending speed to load weight to ensure stability during two-person operations, with noise controlled within 78dB.

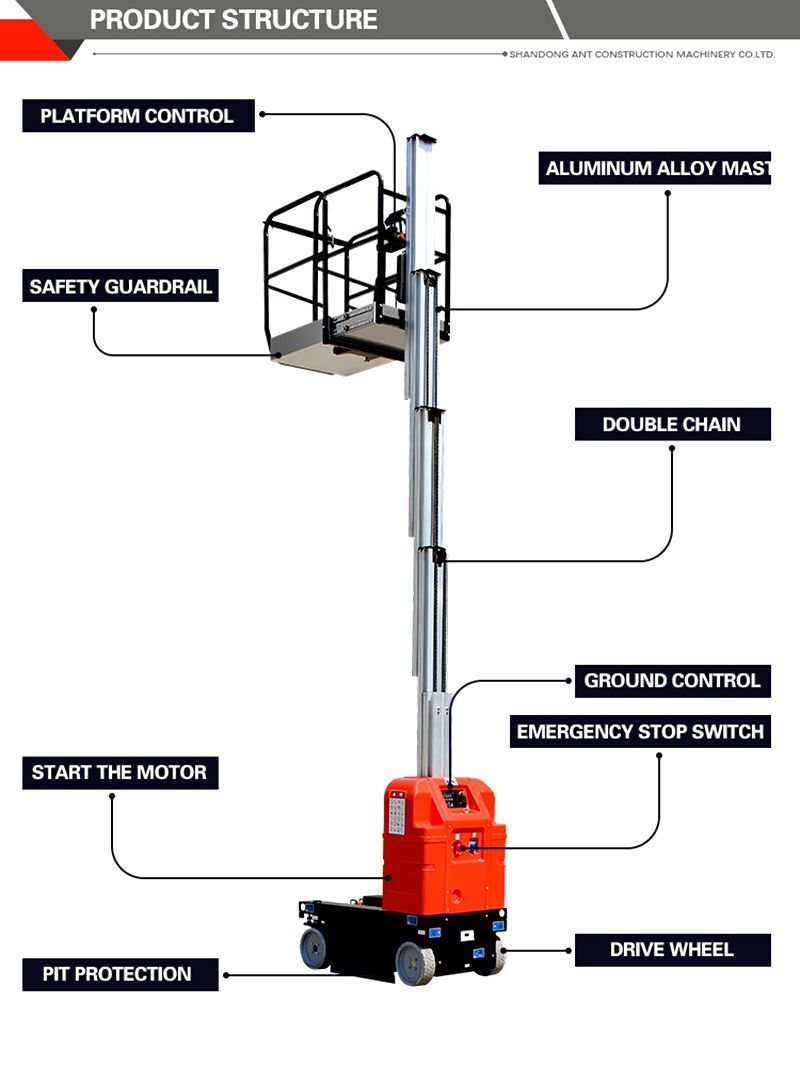

Multi-Layer Safety Protection System: Comprehensive Assurance for Two-Person Operations

Structural Safety: Dual-column profiles are strengthened by T6 heat treatment, with tensile strength reaching 240MPa. Outriggers lock doubly with mechanical pins and hydraulic locks. An audio-visual alarm triggers and disables lifting when the tilt angle exceeds 3°; a pressure sensor cuts power interlocks to prevent overload tipping if the load exceeds 275kg (110% of rating).

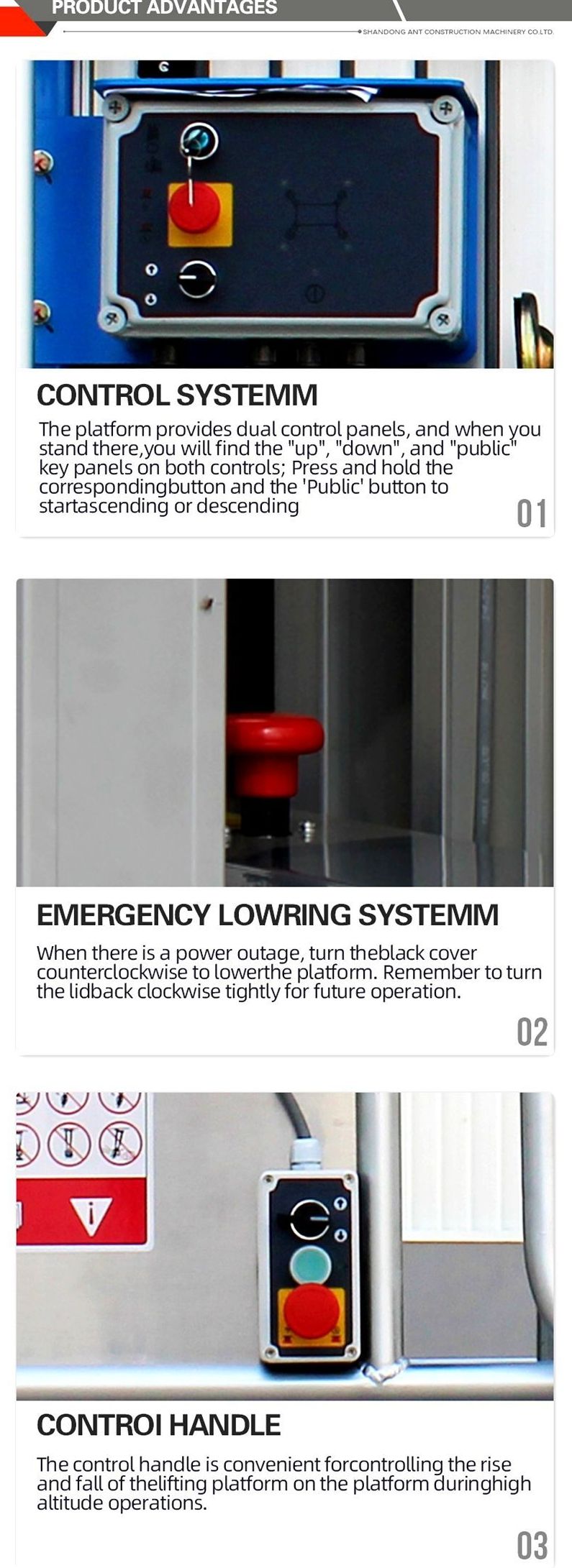

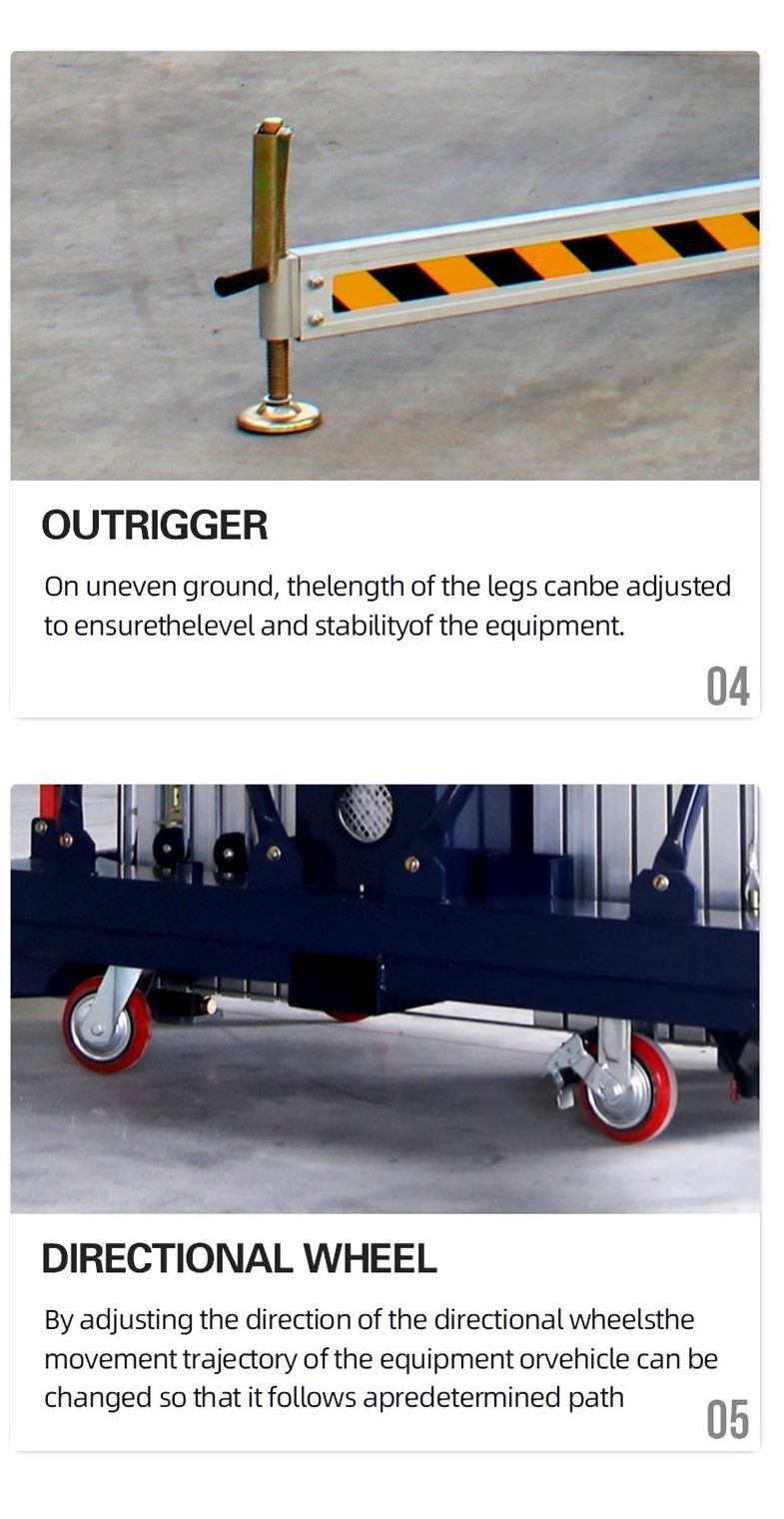

Operational Safety: Both ground and platform dual-control panels feature IP65 waterproof emergency stop buttons. A manual pump enables emergency descent during power outages. Dual limit switches at the top of dual columns prevent over-travel, and bottom buffer devices avoid impact—compliant with GB/T 27548-2011 aerial work equipment safety standards.

Spatial Safety: The 1.45m × 0.7m platform standardly includes 1.1m-high guardrails and kickplates. Anti-slip strips on the edges prevent tool slip-off. A 200mm extension plate is optional (purchased separately) to expand the work area.

Full-Scene Two-Person Operation Solutions

Commercial Complex Applications: Two-person collaborative lighting replacement in mall atriums (platform load supports 2 persons + lighting tools) and high-altitude decoration installation in hotel lobbies. The 1.99m retracted height fits passenger elevator transport, reducing aerial work preparation time.

Industrial Maintenance Scenarios: Two-person cooperative maintenance of overhead conveyor lines in automotive assembly plants and joint inventory of 10m-high shelves in logistics warehouses. The dual-column structure reduces operational sway, enhancing precision operation stability.

Municipal and Construction Projects: The DC version supports two-person streetlight maintenance in outdoor off-grid environments and two-person exterior wall painting for small buildings. The outrigger support system remains stable on slopes ≤5° or soft ground.

Ergonomic and Maintenance Design

Control Experience: Platform handrails integrate variable frequency speed control buttons, supporting 0.3–0.6m/s lifting speed adjustment with ±35mm positioning accuracy. The ground control panel displays intelligent fault codes for quick troubleshooting of motor overheating, battery undervoltage, etc.

Transition Efficiency: The body is equipped with four universal load-bearing wheels, allowing two persons to push for short-distance movement. Outriggers feature quick-release design, completed by two persons within 45 seconds—30% more efficient than single-column platforms.

Maintenance Cost: Dual-column structure uses maintenance-free self-lubricating bearings. The sealed hydraulic system blocks dust, reducing annual maintenance costs by 40% compared to similar steel platforms. Key components (cylinders, motors) adopt modular design, supporting quick replacement within 30 minutes.

Core Technical Highlights

The ATWY2-6 breaks through single-operator limitations with its dual-column outrigger design. The 250kg load capacity and 6m platform height form a golden combination for two-person medium-high altitude work, suitable for scenarios requiring collaborative operations and large tool carrying. Dual-power configurations cover on-grid/off-grid environments, and multi-layer safety protection provides reliable assurance for two-person operations—making it the preferred equipment to enhance aerial work efficiency in commercial, industrial, and municipal sectors.

Russian

Russian