4.7 m Flexible Single Column Outrigger Mobile Aluminum Platform For Sale

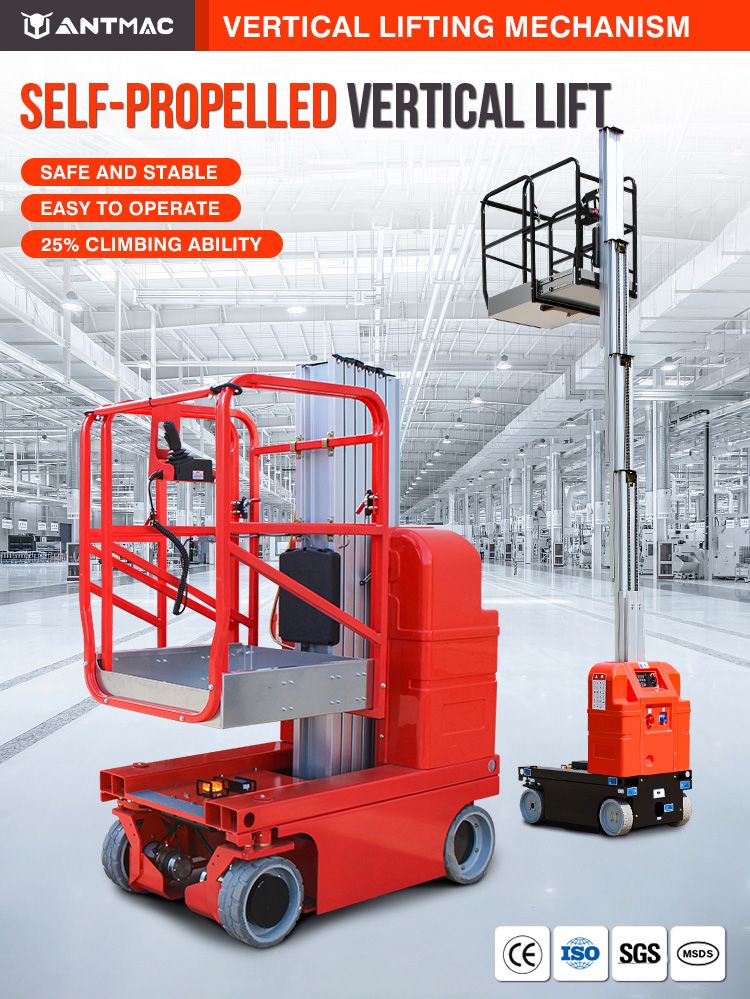

ATWY1-5 Single-Column Outrigger Aluminum Mobile Platform: A Flexible Solution for Narrow-Space Aerial Work

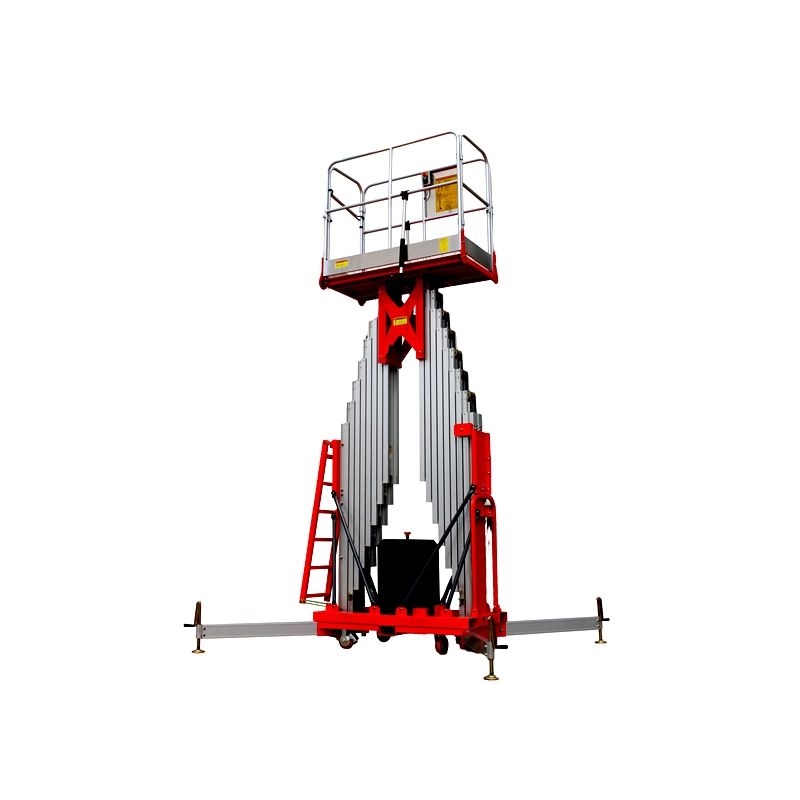

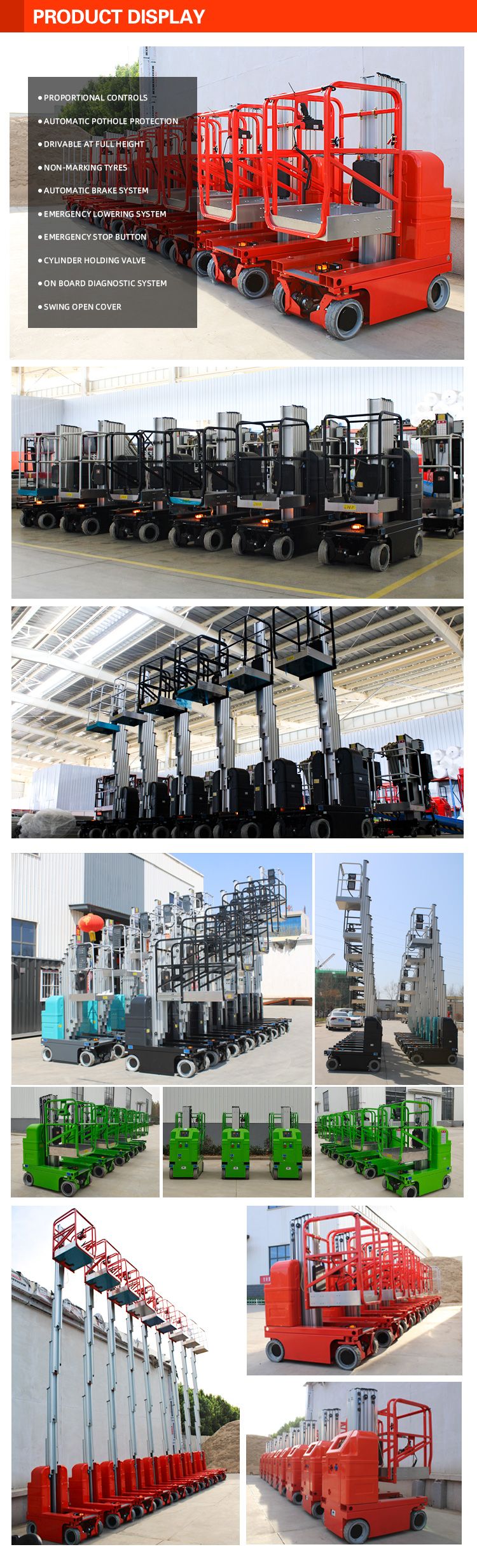

Outrigger Structure Design: Innovative Fusion of Stability and Passability

Designed for narrow spaces, the ATWY1-5 single-column outrigger aluminum platform uses high-strength 6063-T5 aluminum extrusions to achieve a 6.7m maximum working height. The retractable outrigger structure keeps the overall weight at 330kg (AC version)/380kg (DC version)—over 50% lighter than traditional steel platforms. With an ultra-compact 1.26m×0.76m frame and 1.99m retracted height, it fits standard elevators (car size ≥1.3m×1.0m) and corridors ≥0.8m wide. The deployed 1.9m×1.8m outrigger coverage, locked by mechanical pins, increases anti-tip moment to 1.5x the rated load, ensuring stability at the 4.7m platform height. The 0.67m×0.66m non-slip platform features guardrail kickplates and 5kg-rated tool hooks for safe single-person operation with small tools.

Dual Power Options: Full-Scene Energy Adaptation

The platform offers two independent power versions:

AC Version: Compatible with 380V/220V/110V industrial and civil power, driven by a 1.5kW asynchronous motor. Ideal for fixed-point, high-frequency use (e.g., factory production line maintenance, mall ceiling inspection), it operates continuously when plugged in, eliminating charging downtime.

DC Version (Optional): Equipped with a 12V battery and 1.5kW DC motor, supporting 6 hours of continuous operation (8 lifting cycles/hour). The 12V/15A smart charger completes a full charge in ~5 hours, suitable for outdoor temporary work, warehouse inventory without fixed power, or mobile scenarios, freeing users from power cords.

Both versions use a hydraulic pump station, with lifting speed ≤12sec/m (4.7m platform in ~56 seconds) and controlled descent via a throttle valve to avoid ground impact.

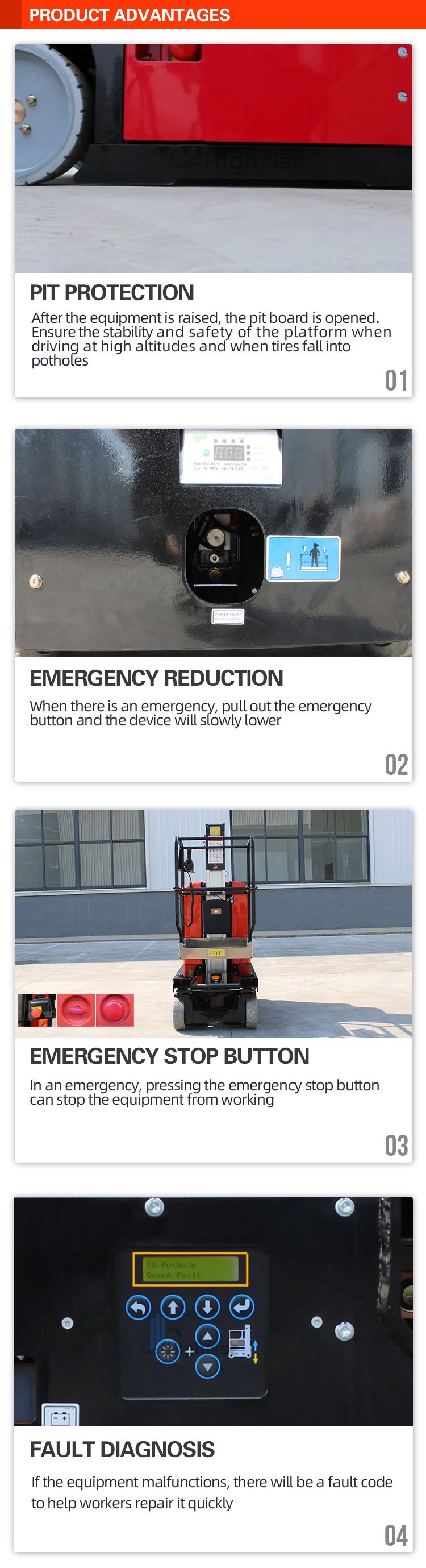

Safety Features: Multi-Layer Protection of Outrigger Structure

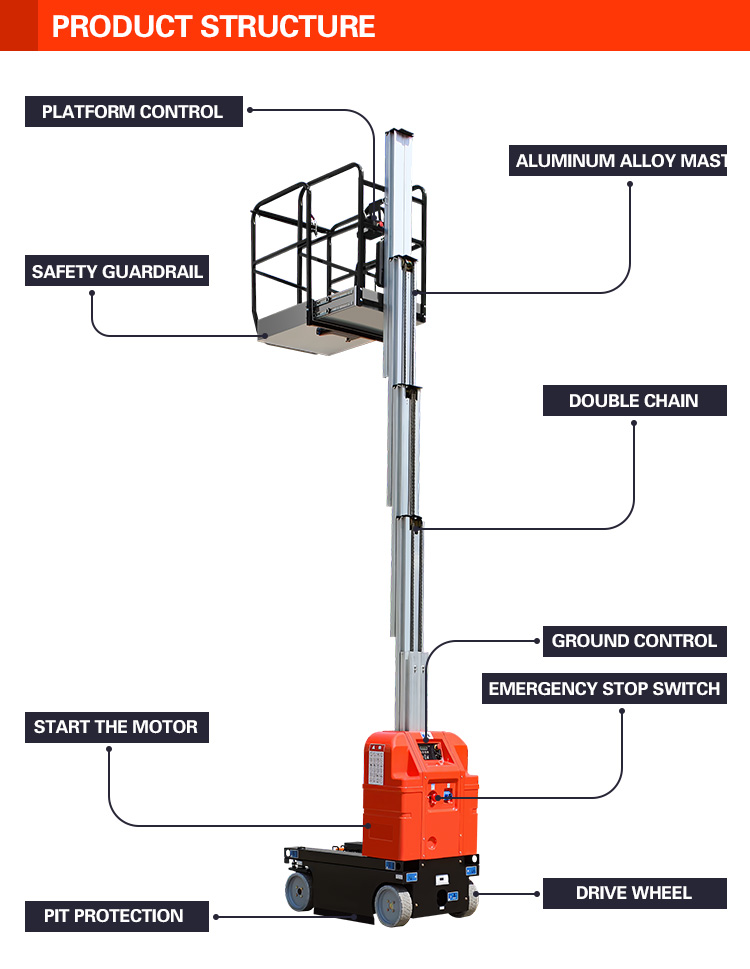

Structural Safety: Outriggers lock with mechanical pins and include a level gauge for real-time support surface monitoring. Audio-visual alarms trigger when the tilt angle exceeds 3°. The hydraulic system cuts off lifting power if the load exceeds 10% of the 150kg rating to prevent overloading.

Operational Safety: Emergency stop buttons on both ground and platform control panels allow manual pump descent during power outages. Dual limit switches at the mast top and bottom prevent over-travel, while a hydraulic lock engages in case of oil pipe rupture, complying with GB/T 27548-2011 Mobile Elevating Work Platforms Safety Rules.

Certifications: CE-certified for machinery safety, key components (cylinders, outrigger joints) pass 2x rated load pressure tests, and aluminum welds undergo X-ray inspection for long-term reliability.

Scenario Adaptability: From Indoor Precision Work to Outdoor Tasks

Indoor Narrow Spaces: Hotel room ceiling maintenance (0.76m width fits bathroom doors), library high-shelf organization (1.99m retracted height suits most indoor ceilings), and electronics factory cleanroom equipment debugging (aluminum is anti-static and spark-free).

Outdoor Mobile Work: The DC version with optional Φ200mm rubber wheels enables easy pushing on mildly uneven surfaces, ideal for municipal streetlight maintenance and residential building facade cleaning. Outriggers ensure stability on slopes (≤5°) or soft ground.

Special Scenarios: Replaceable outrigger pads (optional) protect sensitive floors like tiles and wood, meeting high commercial ground protection standards.

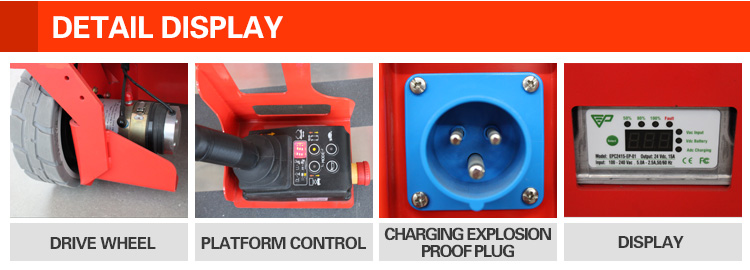

Technical Details and Ergonomic Design

Control System: The AC version uses an electromagnetic directional valve, while the DC version employs a DC contactor, both supporting jog lifting with ±30mm positioning accuracy for precise tasks like pipe alignment.

Portability: A foldable handle on the body allows short-distance manual movement. Quick-release outriggers enable single-person deployment/retraction within 30 seconds for efficient site transitions.

Maintenance Advantages: Self-lubricating bearings reduce maintenance frequency, and a sealed hydraulic tank prevents dust ingress, cutting annual maintenance costs by 30% compared to similar products. Standard fault indicators quickly identify electrical issues.

The ATWY1-5 breaks through in compact framing, stable support, and power flexibility via its outrigger structure, becoming an efficient tool for single-person aerial work. Optional accessories—rain cover, platform extension, wireless remote—support customized power systems for industries (e.g., explosion-proof, low-temperature), providing safe and convenient aerial solutions for manufacturing, services, and municipal maintenance.

Russian

Russian