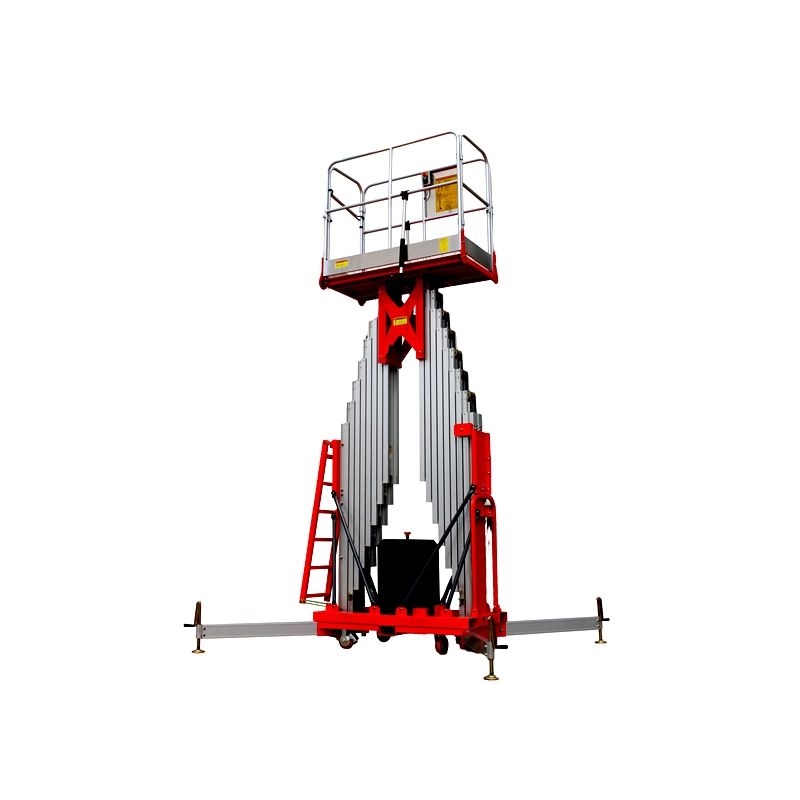

6m Lightweight Single Column Aluminium Alloy Lifting Platform For Sale

ATWP6-1100 Self-Propelled Single-Column Aluminum Lifting Platform: A Flexible Solution for Single-Operator Aerial Work

Single-Column Core Design: The Pinnacle of Lightweight Mobility

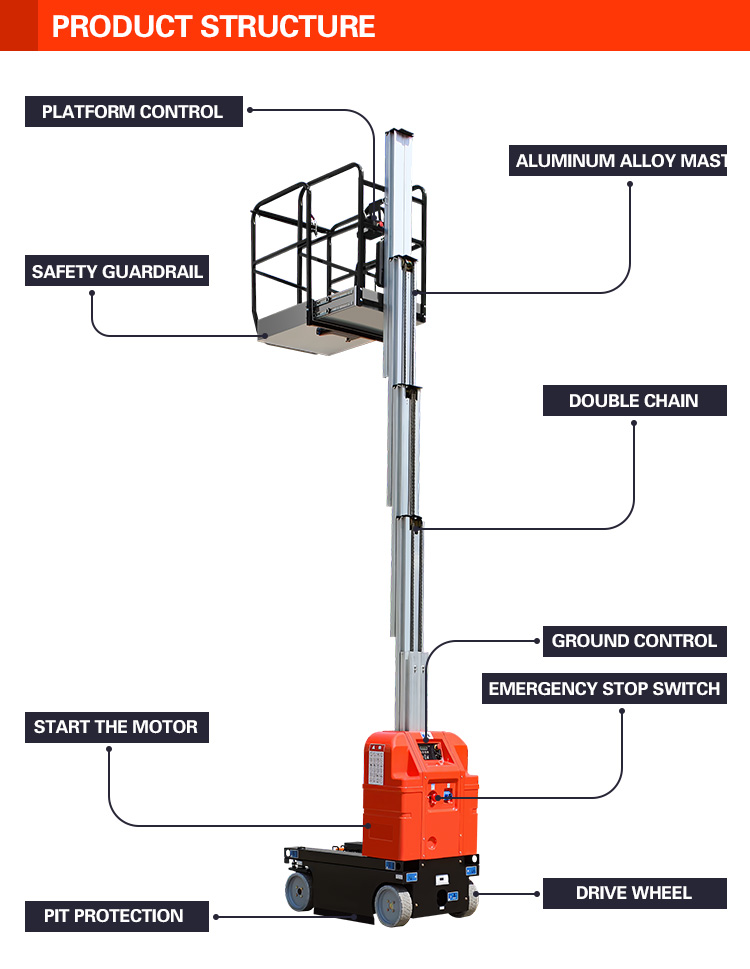

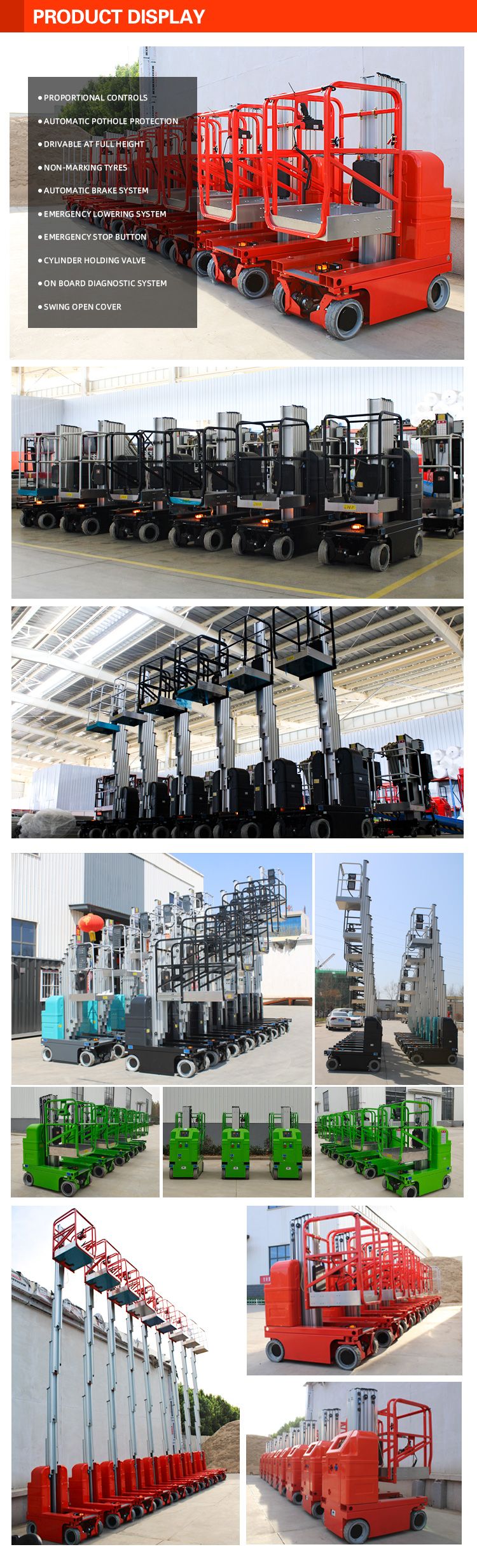

As a self-propelled single-column aluminum platform, the ATWP6-1100 achieves an 8-meter maximum working height with a single-mast structure. Constructed from high-strength 6061-T6 aluminum extrusions, the entire unit weighs only 1,120kg—25% lighter than dual-column platforms. Its compact 1.4m × 0.76m frame, paired with a 0.3m minimum turning radius, enables in-situ rotation in corridors and among shelves. This design allows single operators to navigate elevators (car size ≥1.5m×1.0m) and narrow passages with ease. The single-column configuration, driven by a central hydraulic cylinder, maintains verticality within ±0.5° during lifting/lowering. The 0.66m×0.67m non-slip platform, though designed for single operators, features standard safety railings and tool hooks (load ≤5kg), catering to light-duty aerial tasks like lighting maintenance and equipment debugging.

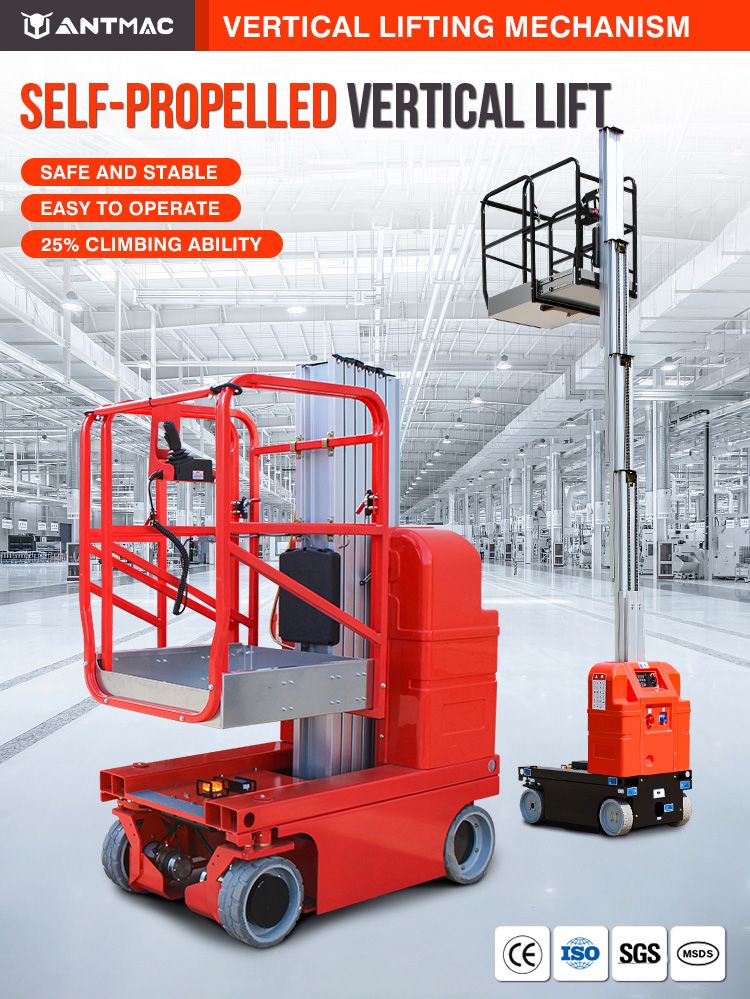

Self-Propelled Functionality: Electric Drive with All-Terrain Adaptability

Equipped with dual 24VDC/0.5kW drive motors, the platform reaches 3.5km/h in the retracted state for short-range transfers within workshops. When elevated, it automatically switches to a 0.8km/h low-speed mode to prevent center-of-gravity shifts. Its 25% gradeability (equivalent to a 14° incline) tackles factory ramps and loading docks, while Φ305×100mm polyurethane drive wheels balance noise reduction and wear resistance—suitable for protecting indoor floors or navigating light outdoor mud. The power system integrates a 2×12V/100Ah maintenance-free lead-acid battery pack, supporting 8 hours of continuous operation (based on 10 lifting cycles per hour). The 24V/15A smart charger, with overcharge protection, completes a full charge in 6-8 hours and adapts to global power interfaces. The pure electric drive ensures zero emissions and noise ≤65dB(A), meeting environmental standards for commercial spaces.

Operational Performance and Safety Features

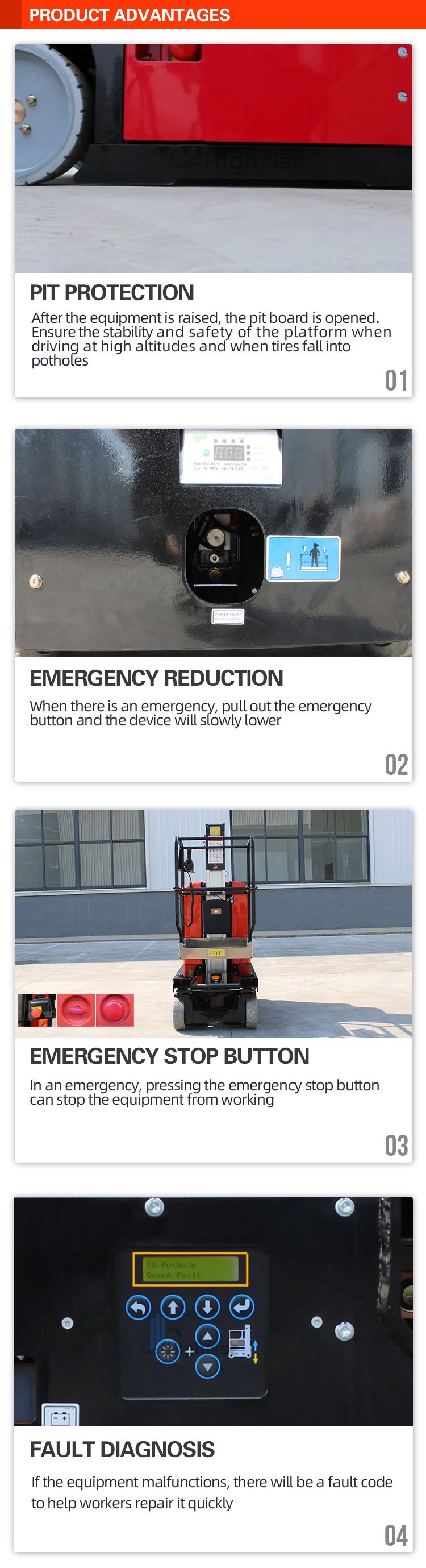

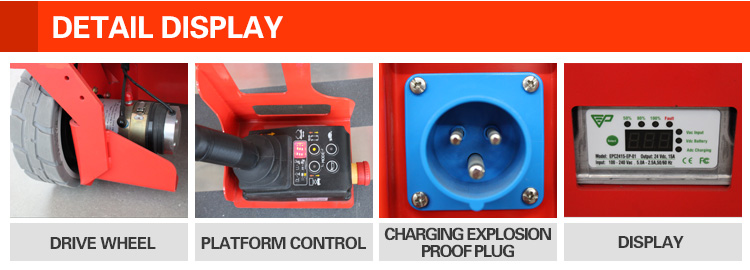

With an 8-meter maximum working height, the single-column structure—optimized for mechanical balance—limits sway to ≤30mm (surpassing the industry standard of ≤50mm). The 150kg platform load capacity accommodates single operators with tools; if loaded beyond 10% of the limit, the hydraulic system automatically locks while triggering audio-visual alarms. Lifting/lowering speeds are controlled at 48s/40s, with a buffer valve ensuring smooth descent to avoid ground impact. Safety configurations include emergency stop buttons on both ground and platform control panels, dual protection from electrical limit switches and mechanical stops at extreme positions, and a hydraulic lock that engages in case of oil pipe rupture. Certified by CE/ISO 9001, the mast’s welds undergo X-ray inspection, and critical components pass 1.5× load testing, complying with EN 280:2013 European safety standards for aerial work equipment.

Scenario Adaptability: The Precision Edge of Single-Column Design

In commercial services, the platform suits tasks like hotel lobby chandelier cleaning, mall ceiling pipeline maintenance, and exhibition booth installation. Its single-column design minimizes space occupation, ideal for atriums and spiral staircases. In industrial applications, it supports electronics factory production line maintenance (aluminum’s anti-static property), warehouse high-shelf inventory management (1.99m retracted height fits standard warehouse doors), and automotive 4S shop roof inspections—all operable by a single person. With an optional rain cover, it adapts to temporary outdoor work such as municipal streetlight maintenance or residential building facade cleaning, while its 25% gradeability handles park road undulations.

Technical Details and Maintenance Advantages

The platform employs a 1.2kW lifting motor with a gear pump, maintaining hydraulic system pressure at 14MPa for smooth, jerk-free operation. The electro-hydraulic proportional control system enables stepless speed adjustment with ±20mm positioning accuracy, suitable for precision tasks like curtain wall gluing. A sealed hydraulic system prevents oil leakage, and maintenance-free bearings reduce upkeep frequency, cutting annual maintenance costs by 40% compared to traditional equipment. The standard fault code display expedites troubleshooting. Human-centric designs—such as anti-slip platform edges, tool slots on handrails, and waterproof covers for ground control panels—balance operational efficiency and comfort.

Russian

Russian