6 M New Heavy-Duty Dual-Mast Aluminum Lift Factory Supply

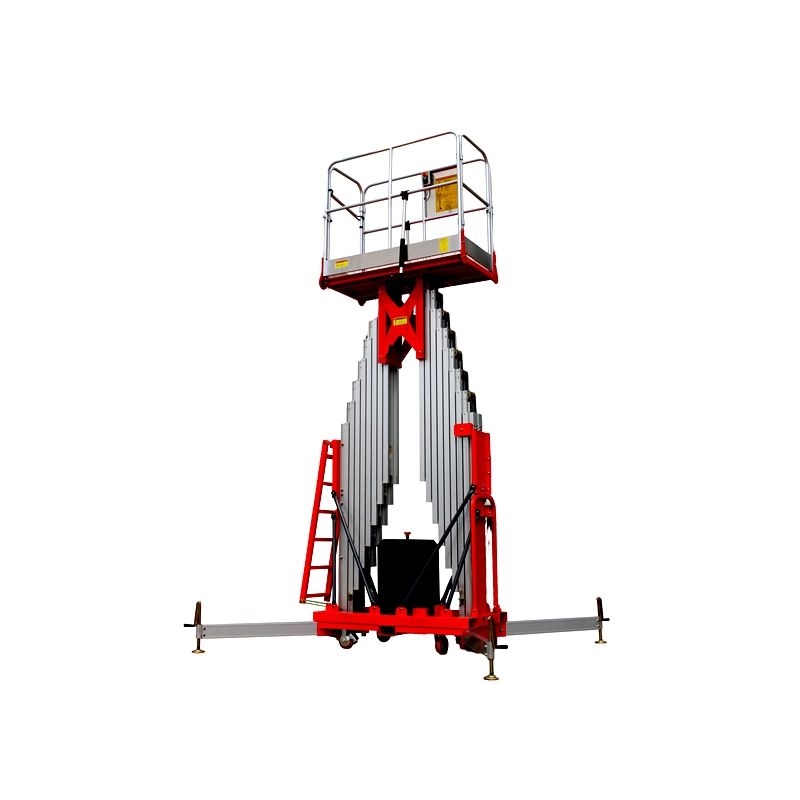

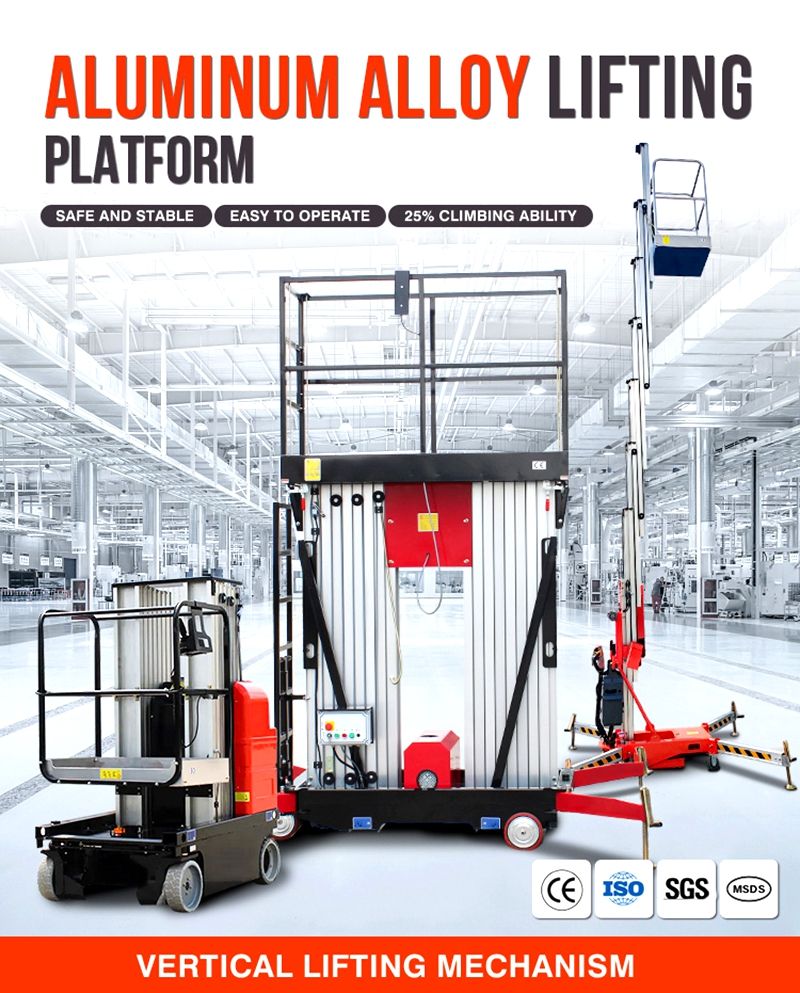

ATWY6-300-2-B Dual-Mast Aluminum Alloy Lifting Platform: "Dual-Mast Load-Bearing Expert" for 6m Heavy-Duty Scenarios

Dual-Mast 300kg Heavy-Duty Breakthrough: A 6m Multi-Person Collaboration Platform

As a heavy-duty model with a dual-mast design, the ATWY6-300-2-B features a core frame made of high-strength, high-quality aluminum alloy. Its dual-parallel mast load-bearing structure achieves stable output of "6m height + 300kg load"—this load capacity is equivalent to 2 people + a full set of heavy tools (such as a 20kg electric hammer + a 15kg cutting machine + a 50kg spare parts box), increasing the load capacity by 100% compared to single-mast platforms of the same height. It completely solves the pain point of "multi-person collaboration or heavy tool transportation at 6m height".

The 1.2×0.63m widened platform is a key support for heavy-duty scenarios: with an area of 0.756㎡, it provides nearly 80% more operational space than conventional 6m platforms. The edges are equipped with 10cm-high anti-slip baffles (2mm pattern depth) that can temporarily hold tools or spare parts to prevent falling. The distance between the dual masts is optimized to 0.8m, ensuring structural stability without affecting personnel turning or tool placement on the platform—especially suitable for collaborative scenarios such as "one operator + one assistant" (e.g., 6m-high pipe installation, heavy cargo racking in warehouses).

Dual-Mast "Stable Yet Not Clunky" Design: Flexible Heavy-Duty Logic at 510kg

The dual-mast main frame adopts a "symmetrical load-bearing" layout. Each mast uses 5mm-thick 6061-T6 aluminum alloy (tensile strength ≥280MPa), with key connection nodes reinforced by stiffeners. Under a 300kg load at 6m height, the overall deflection is ≤2mm, and stability is 40% higher than that of single-mast platforms.

The 510kg overall weight is balanced through "material gradient distribution": load-bearing parts are thickened to 5mm, while non-load-bearing parts are reduced to 3mm—15% lighter than dual-mast platforms with the same load capacity. Combined with ergonomic push-pull handrails, the towing resistance for a single person on flat ground is ≤60N (equivalent to pulling a medium-sized washing machine). With external dimensions of 1.55×0.85×2.0m, it can pass through 1m-wide workshop passages and freight elevators, with a turning radius of 1.8m, enabling flexible movement in supermarket shelf areas and factory equipment gaps—breaking the perception that "heavy-duty must be clunky".

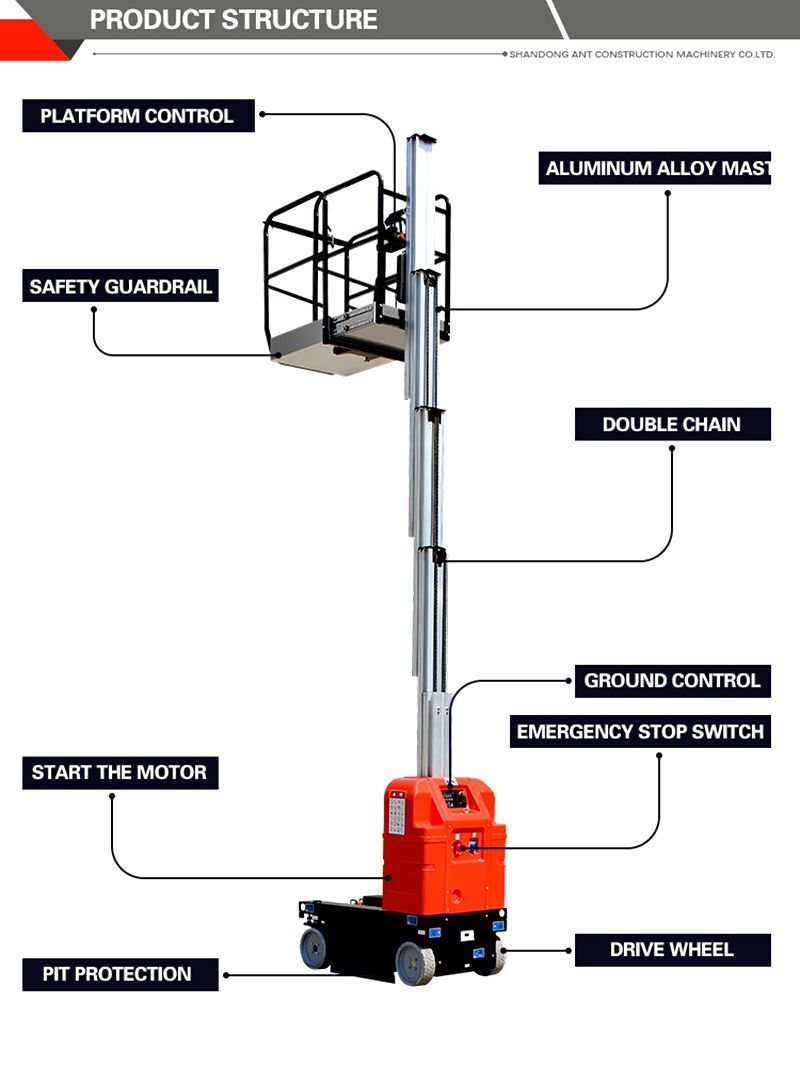

1.5kW Power Adaptation: Efficient Lifting Guarantee for 300kg Load

The 1.5kW motor optimizes the hydraulic system for 300kg loads and 6m height, achieving a lifting speed of 0.4m/s (only 15 seconds to rise from the ground to 6m)—20% faster than platforms with the same load capacity. The hydraulic pump flow is increased to 12L/min, ensuring synchronized lifting of dual masts (with an error ≤1mm) and preventing tools from sliding due to platform tilting.

After 4 hours of continuous heavy-duty operations (lifting once every 10 minutes, carrying 300kg each time), the motor temperature rise is ≤45℃, and the body surface temperature is ≤50℃, making it suitable for high-frequency cargo transfer in enclosed warehouses in summer. The 220V power supply is compatible with optional 110V wide-range input, operating stably in workshop environments with ±10% voltage fluctuations without the need for additional voltage stabilizing equipment.

Dual-Mast Exclusive Safety System: All-Dimensional Protection for Heavy-Duty Scenarios

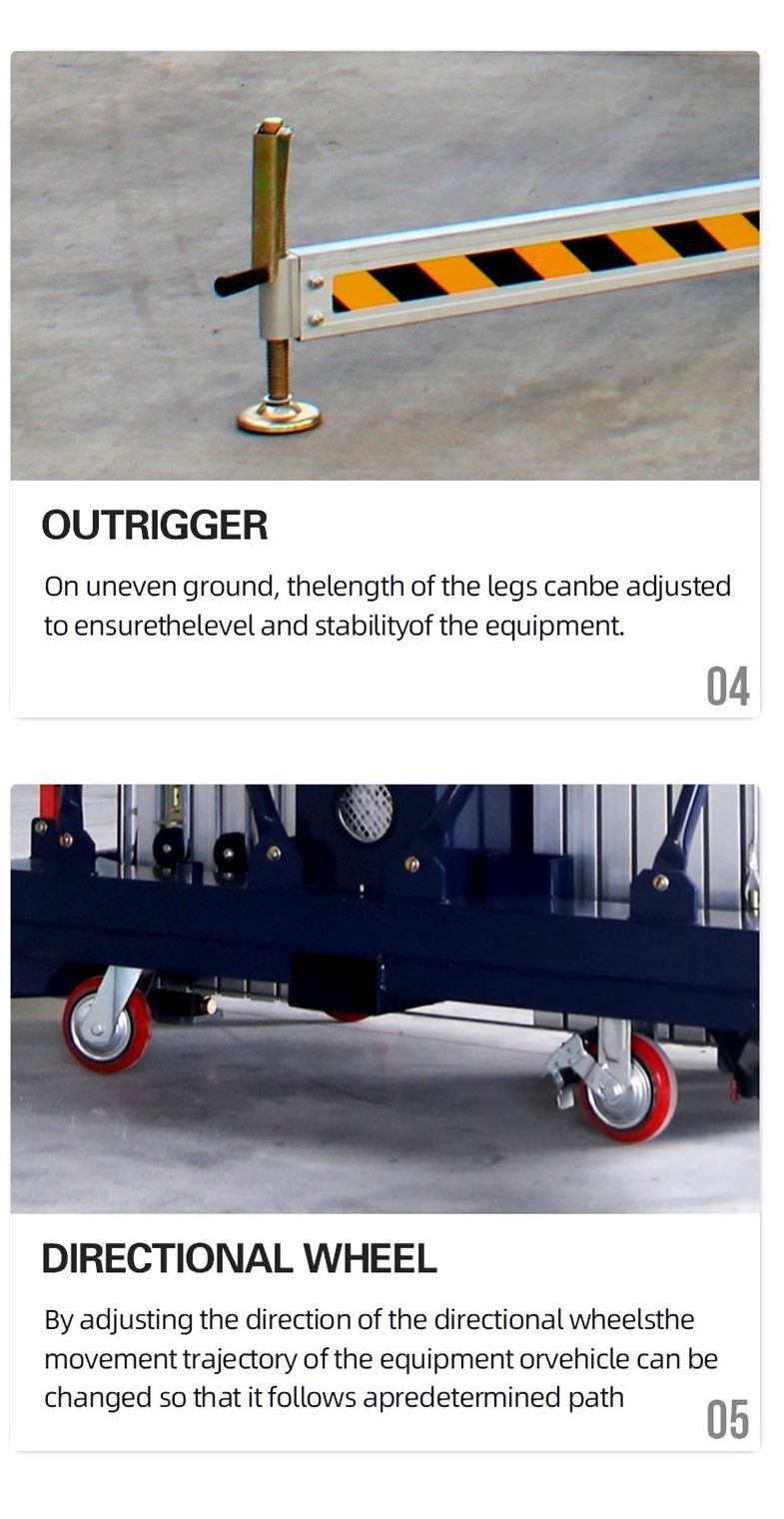

Dual-Mast Anti-Tilting Advantage: The level gauge uses dual-axis monitoring (sampling frequency 20Hz). When tilting exceeds 3°, both masts trigger locking synchronously (single masts only lock on one side). Combined with 1.8×1.5m hidden outrigger support (ground pressure ≤0.3MPa), it can resist slight ground unevenness (height difference ≤10mm) under a 300kg load, avoiding rollover risks.

Heavy-Duty Buffering Design: The hydraulic system automatically activates "buffering mode" during lifting start and stop, with platform vibration amplitude ≤2mm, preventing tools from shifting due to inertia under 300kg loads (such as heavy welding machines and metal pipes). Chain protection is heightened to 1.2m, forming an enclosed space with lifting guardrails to prevent personnel from accidentally leaning out during heavy-duty operations.

Emergency Heavy-Duty Guarantee: The emergency descent valve is upgraded with a "dual-path pressure relief" structure for 300kg loads. In case of power failure, the descent speed can be controlled via a knob (0.2-0.3m/s). Combined with a manual pump backup system (dual masts distribute force more evenly, making manual operation easier), it can lower from 6m to the ground within 30 seconds, eliminating the risk of being stranded under heavy loads.

Mobility and Details: A "Quiet and Lightweight" Experience Under Heavy Loads

Polyurethane tires are upgraded to "wide tread + deep pattern" (90mm tread width, 3mm pattern depth) with walking noise ≤60dB, avoiding disturbance when moving in quiet environments such as shopping malls and hospitals. The tire body is reinforced with a steel wire layer, with tire deformation ≤5mm under a 300kg load, leaving no indentations on epoxy floors or wooden floors and showing no obvious wear after 10,000 meters of cumulative walking.

The bottom of the platform is pre-equipped with 4 fixing holes (10mm in diameter) that can secure heavy equipment (such as small generators and welding machines) with bolts, preventing equipment from sliding during lifting. The remote controller uses a 2.4G anti-interference module, maintaining a 10m control distance even in metal shelf and equipment-dense areas, and supports "inching lifting" (accuracy ±5mm)—suitable for precise alignment operations at 6m height (such as pipe docking and billboard installation).

Configuration Expansion: Customized Solutions for Heavy-Duty Scenarios

Core Adaptation of the Basic Version: Dual-mast heavy-duty structure + 300kg load capacity + a full set of safety devices meet regular heavy-duty needs such as multi-person restocking in warehouses and heavy equipment maintenance in workshops.

Scenario-Based Upgrades:

Battery-powered lifting version (12V/120Ah): 5-hour battery life, suitable for outdoor 6m-high billboard installation (without mains electricity), capable of completing 30 heavy-duty lifts on a single charge;

Explosion-proof motor version (Ex dⅡBT4): The entire machine is anti-static, suitable for 6m-high heavy pipeline inspection in chemical workshops (carrying explosion-proof tools), preventing sparks from igniting gases;

Auxiliary walking version: Equipped with dual drive wheels (2km/h speed), allowing a single person to push equipment carrying 300kg during heavy-duty transfers in large logistics parks, reducing manpower by 80%.

Key Scenarios: Exclusive Value of 300kg Load at 6m Height

Heavy-Duty Restocking in Logistics Warehouses: The dual-mast platform carries 2 people + 300kg of goods (about 15 standard cartons), completing top-level shelf restocking at 6m height and reducing round trips by 50%;

Equipment Installation in Industrial Workshops: The 1.2m-wide platform holds 200kg pipes + 2 operators, completing air duct docking at 6m height—dual-mast stability prevents pipe installation deviation;

Heavy Maintenance in Commercial Venues: Carrying 150kg lamps + 2 installers, it replaces large shopping mall chandeliers at 6m height, with remote control reducing manual adjustments at high altitudes;

Heavy-Duty Municipal Engineering Operations: Carrying 250kg of guardrail materials + 1 worker, it completes road barrier installation at 6m height—the battery-powered version eliminates cable restrictions.

Product Positioning: "Dual-Mast Efficiency Benchmark" for 6m Heavy-Duty Operations

With its core combination of "dual masts + 300kg + 6m", the ATWY6-300-2-B fills the gap where "heavy load and flexibility cannot coexist" at 6m height. It ensures the stability of 300kg loads through the dual-mast structure while achieving flexible movement with a lightweight design, transforming multi-person collaboration and heavy tool transportation at 6m height from "relying on large machinery" to "efficient and convenient operations"—becoming an exclusive solution for heavy-duty scenarios in logistics, industry, and commerce.

Russian

Russian