9m Propelled Double Column Aluminum Lift Platform Buy

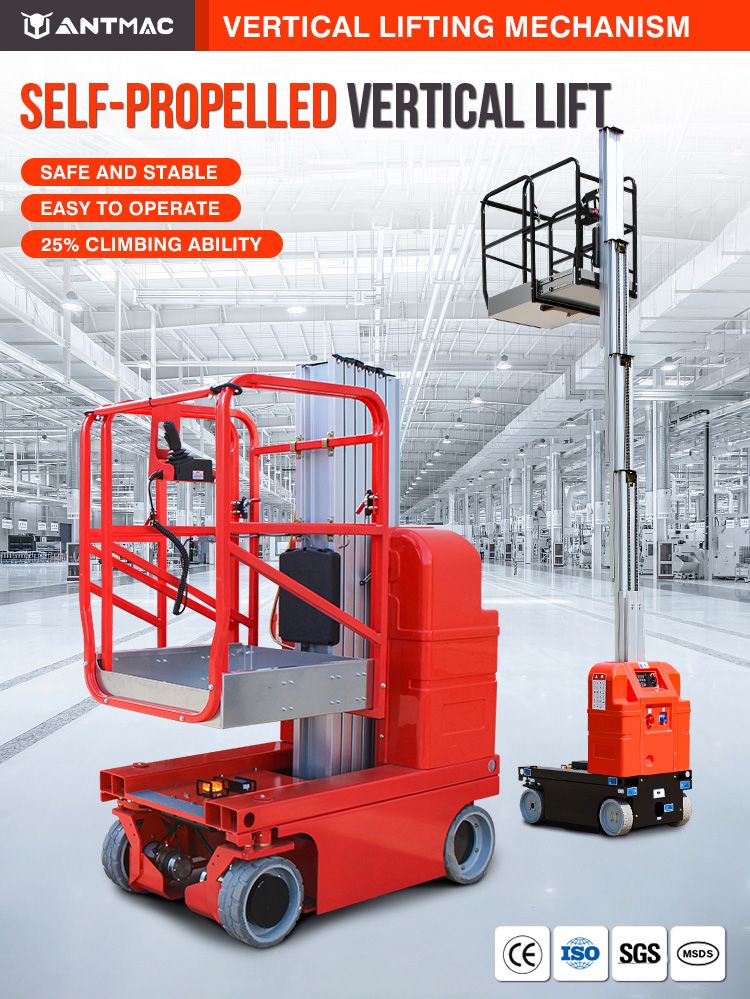

ATWP9-2100 Self-Propelled Double-Column Aluminum Lifting Platform: The Optimal Solution for 9m Medium-High Aerial Work

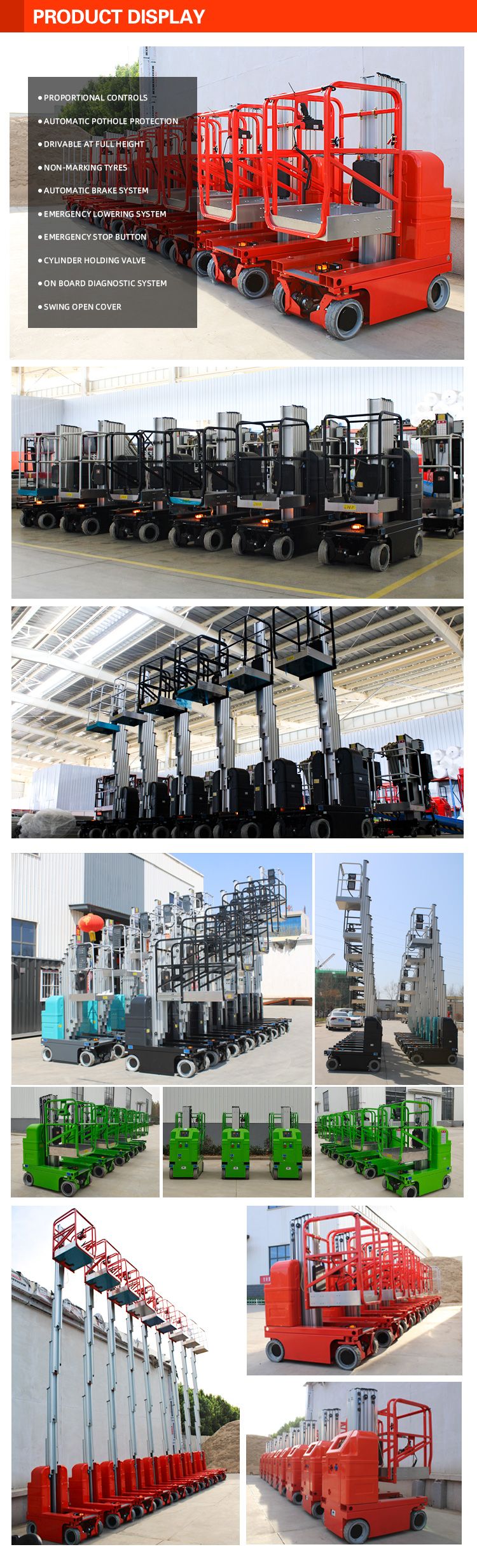

Double-Column Structure: A Paradigm of Stability and Height Balance

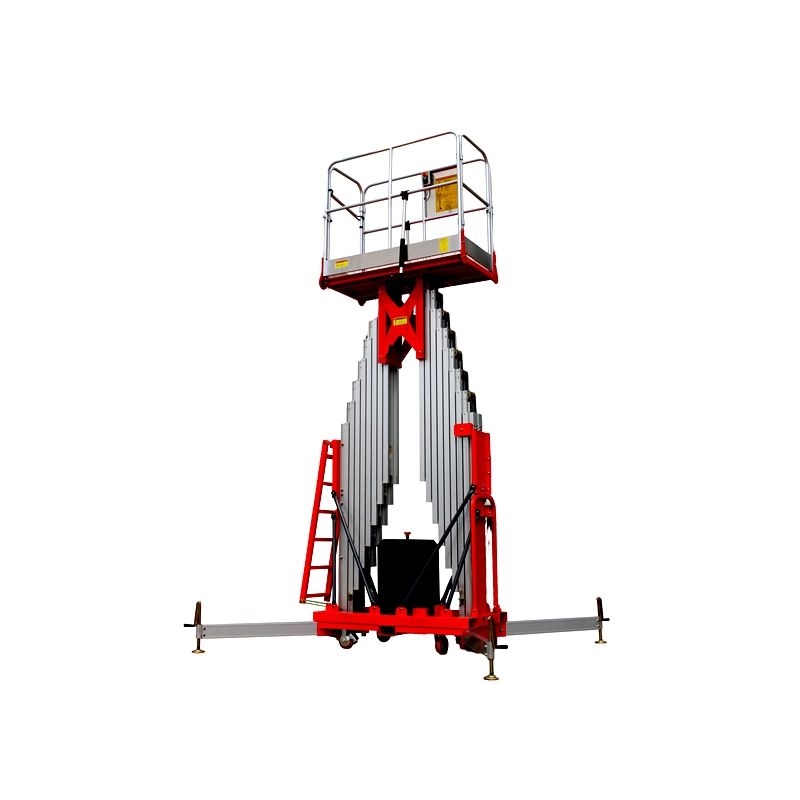

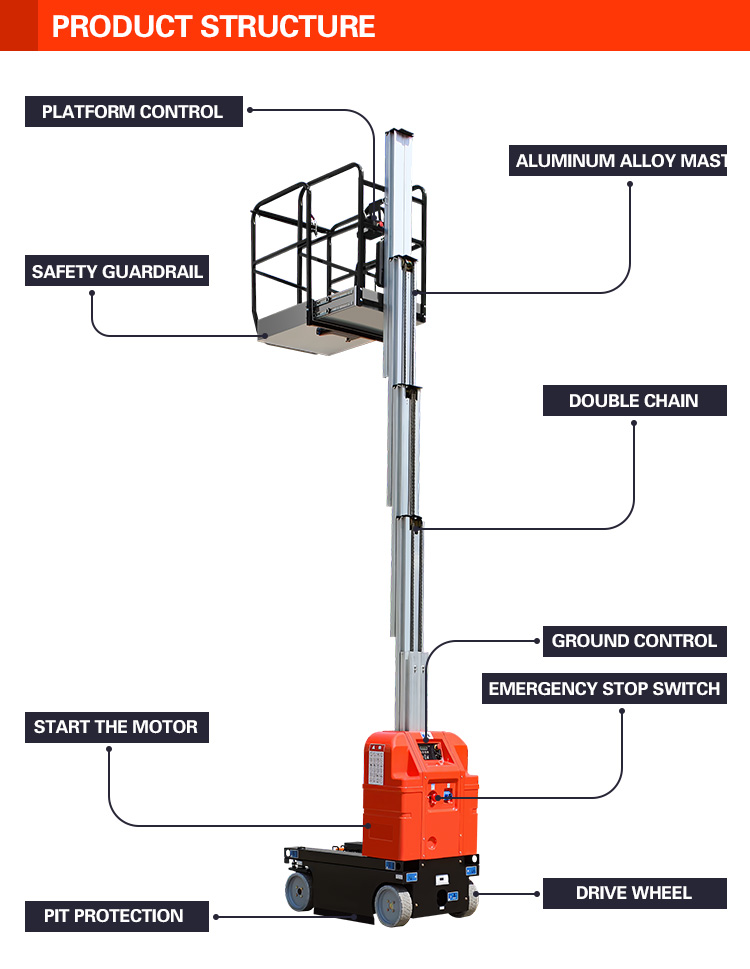

As a high-performance self-propelled double-column aluminum platform, the ATWP9-2100 features a symmetrical double-mast configuration constructed from high-strength 6061-T6 aluminum extrusions. Achieving an 11m maximum working height, it ensures a 150kg platform load capacity (including personnel and tools). The compact 1.46m × 1.01m frame, paired with a 0.3m minimum turning radius, balances double-column stability with spatial flexibility, easily navigating standard industrial doors (width ≥1.1m) and most elevator cars (size ≥1.5m×1.2m). Driven by synchronized hydraulic cylinders, the double-mast design maintains platform verticality within ≤0.3° during lifting/lowering. The 1.00m×0.65m non-slip platform, equipped with dual guardrails and 10kg-rated tool hooks, provides a secure operational space for single-person aerial work.

Power System and All-Terrain Mobility

Equipped with dual 24VDC/0.5kW drive motors, the platform reaches 4km/h in the retracted state for rapid in-plant transfers. When elevated, it automatically switches to an 1.1km/h low-speed mode, combined with a 1.14m wheelbase and double-column balance design, minimizing rollover risks during aerial operations. Its 25% gradeability (equivalent to a 14° incline) tackles factory ramps and loading docks, while Φ305×100mm polyurethane drive wheels balance wear resistance and noise reduction—protecting epoxy floors indoors and stabilizing on light gravel outdoors. The 2×12V/100Ah maintenance-free lead-acid battery pack supports 7 hours of continuous operation (6 lifting cycles per hour), with a 24V/15A smart charger completing a full charge in 6–7 hours, adaptable to global 110–240V power supplies. The zero-emission electric drive ensures ≤68dB(A) noise, meeting environmental and quiet-operation standards for industrial and commercial settings.

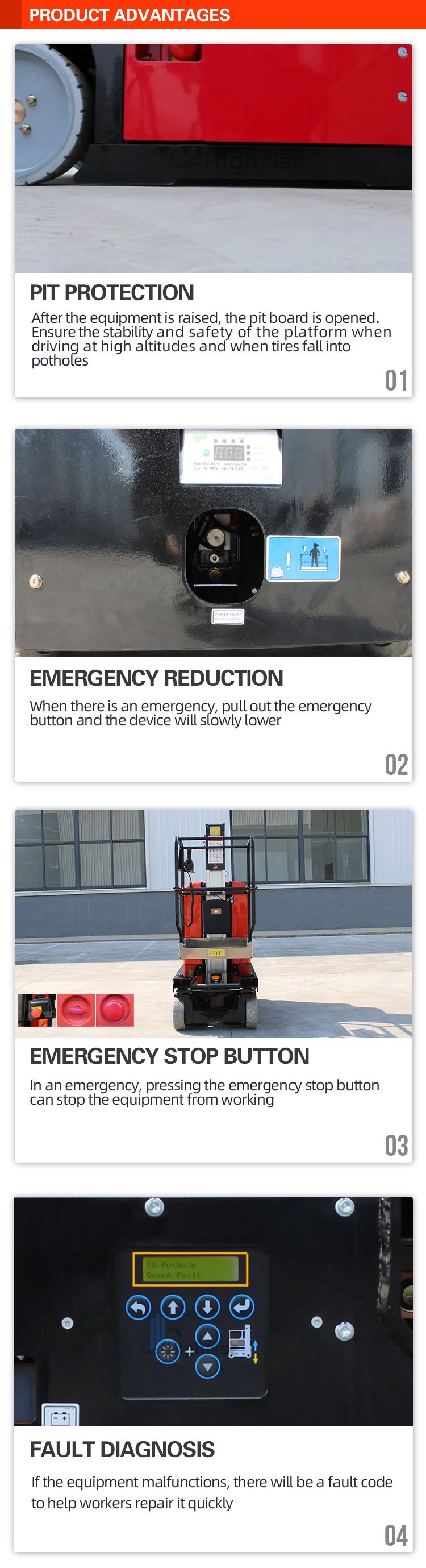

Operational Performance and Safety System

Efficient Vertical Operation: With a 9m platform height and 56-second smooth lifting, the 11m working height covers most industrial and commercial aerial needs. The 49-second buffer descent prevents ground impact, ideal for precision tasks like instrument installation or curtain wall gluing.

Multi-Layer Safety Protection: The finite element-optimized double-column structure withstands 10.8m/s (Class 6 wind) with ≤25mm sway—exceeding industry averages. Overload protection (≥165kg) automatically cuts power with audio-visual alarms, while dual electrical-mechanical limit switches prevent over-travel, and a hydraulic lock engages in case of pipe rupture. CE/ISO 9001 certified, key welds undergo ultrasonic testing, and core components (cylinders, motors) pass 1.5× rated load durability tests for long-term reliability.

Scenario Adaptability and Load Advantages

Industrial Applications: Ideal for automotive workshop overhead pipe maintenance, warehouse high-shelf inventory (150kg load supports medium tool sets), and machinery factory equipment top 检修 (inspection), the double-column design ensures stability under medium loads.

Commercial Solutions: For 9m hotel lobby chandelier maintenance, mall atrium large lighting installation, or exhibition booth construction, the 1.00m×0.65m platform accommodates single operators with large tools, with a compact frame enabling flexible movement in complex spaces.

Special Environments: With an optional platform extension board (expanding to 1.5m×0.65m), it suits wind turbine tower inspections or ship cabin work, while a rain cover adapts to outdoor tasks like municipal streetlight maintenance or building facade cleaning, with 25% gradeability for cabin ramps.

Technical Details and Human-Centric Design

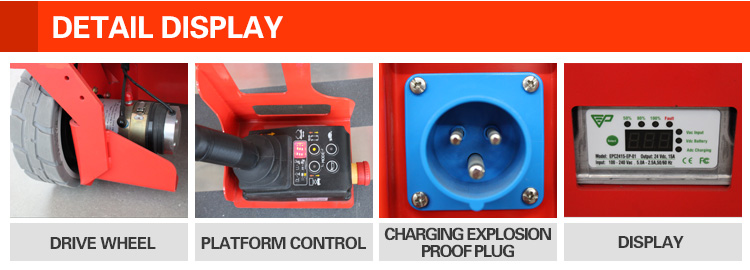

Hydraulic and Control Systems: The 1.3kW high-torque lifting motor with a gear pump maintains 16MPa hydraulic pressure, enabling stepless speed adjustment with ±15mm positioning for precise tasks like pipe alignment. IP65-rated dual control panels (ground/platform) integrate emergency stops and speed knobs on platform handrails for intuitive operation.

Maintenance and Durability: A sealed hydraulic tank prevents contamination, while maintenance-free bearings reduce upkeep by 30% compared to traditional double-column platforms. A built-in fault diagnostic display real-time monitors battery level, motor temperature, and operation hours, accelerating troubleshooting.

Ergonomic Enhancements: Anti-collision rubber strips protect the body in narrow spaces, while the 0.3m turning radius allows navigation in <1.2m aisle widths. Non-slip platform edges and guardrail kickplates further enhance safety.

Core Advantages Summary

The ATWP9-2100 balances a 9m platform height, 150kg load capacity, and compact frame through its innovative double-column design, making it ideal for medium-high aerial tasks. Optional accessories—wireless remote control, lithium battery upgrades, custom guardrail extensions—support tailored solutions for industries like explosion-proof environments or low-temperature operations, empowering global customers to efficiently complete aerial equipment maintenance, installation, and inspection tasks.

Russian

Russian