10.4 m Stable Single-Column Outrigger Aluminum Lift Platform For Sell

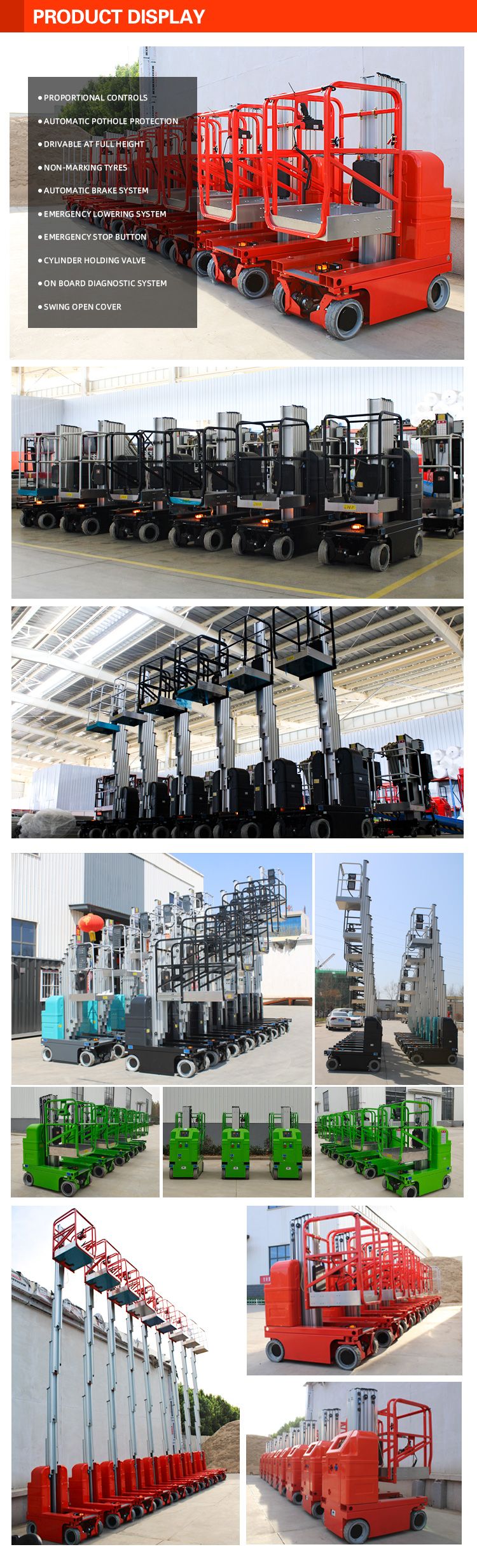

ATWY1-10 Single-Column Outrigger Aluminum Lifting Platform: The Lightweight Choice for 10.4m Aerial Work

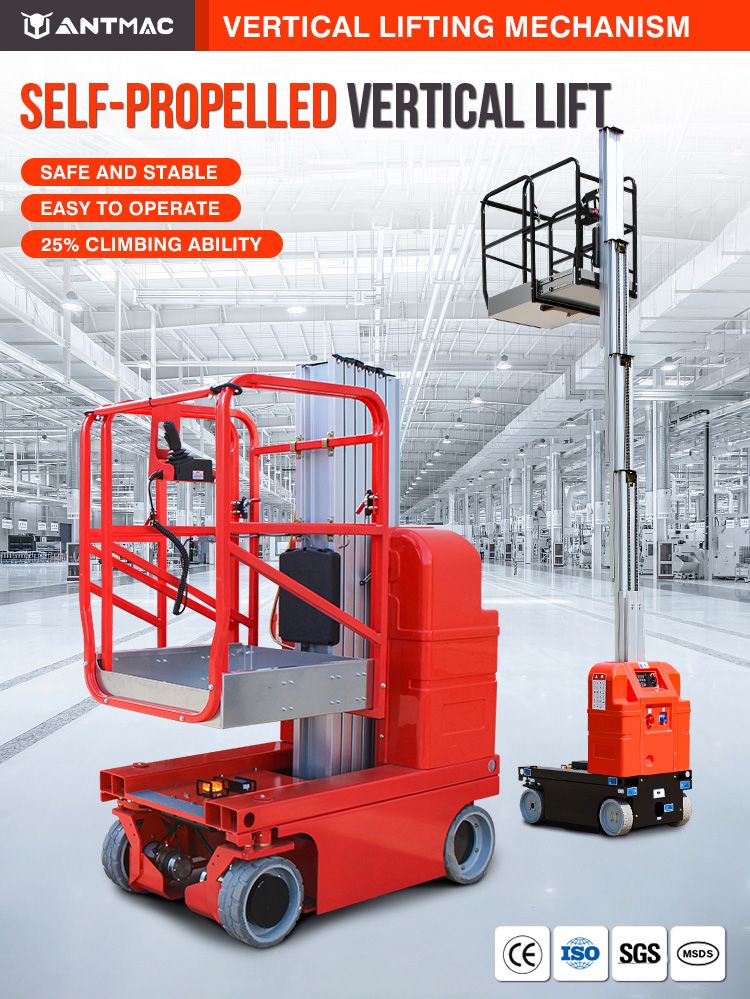

Product Positioning

Engineered as a lightweight solution for medium-high altitude operations in narrow spaces, the ATWY1-10 offers a 10.4m platform height and 136kg load capacity, suitable for single-operator indoor/outdoor tasks such as equipment maintenance, facility installation, and inspection cleaning.

Core Architecture and Materials

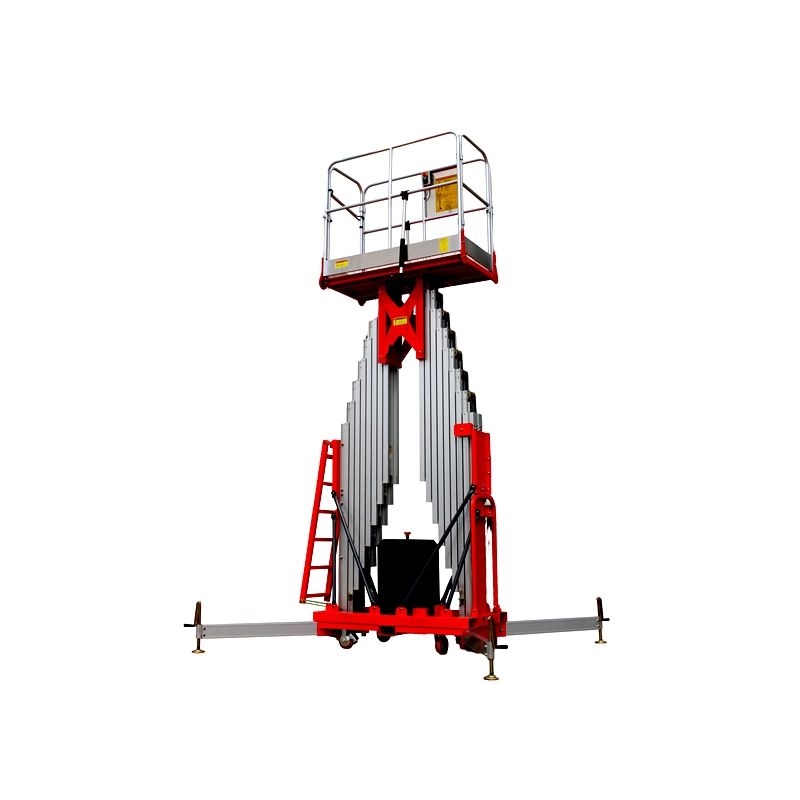

Constructed from high-strength 6061-T6 aluminum alloy extrusions in a single-column outrigger design, the platform reduces overall weight by over 40% compared to steel counterparts, balancing lightweight performance with corrosion resistance. The retracted dimensions—1.4m (L) × 0.76m (W) × 1.99m (H)—fit standard elevators (car size ≥1.4m × 1.1m) and passages ≥0.8m wide, enabling access to confined indoor spaces. The deployed outrigger coverage of 2.1m (front-rear) × 2.0m (left-right) forms a triangular stable structure via mechanical locking, enhancing anti-tip capability on uneven surfaces.

Performance Parameters

Model: ATWY1-10

Max. Working Height: 12.4m

Max. Platform Height: 10.4m

Platform Load Capacity: 136kg (including operator and tools)

Occupants: 1 person

Platform Dimensions: 0.67m × 0.66m (non-slip surface)

Weight (AC Version): 430kg

Weight (DC Version, optional): 480kg

Power System

Dual-Power Configuration (Select as Needed)

AC Power (Standard):

Supports 380V/220V/110V three-phase/single-phase power input with a 1.5kW AC motor, ideal for high-frequency indoor use at fixed workpoints (e.g., factory production line maintenance, mall ceiling installation), enabling continuous operation via constant power supply.

DC Power (Optional):

Features a 1.5kW DC motor with 12V power supply (battery pack required separately), charged by a 12V/15A charger. Full charge supports 5–6 hours of continuous operation (depending on lifting frequency), suitable for outdoor off-grid scenarios like municipal streetlight maintenance or small-site temporary lifting.

Lifting Performance

Equipped with a gear pump hydraulic drive system, the platform achieves ≤15 seconds/m lifting/descending speed (varies by load), operating smoothly with noise ≤75dB.

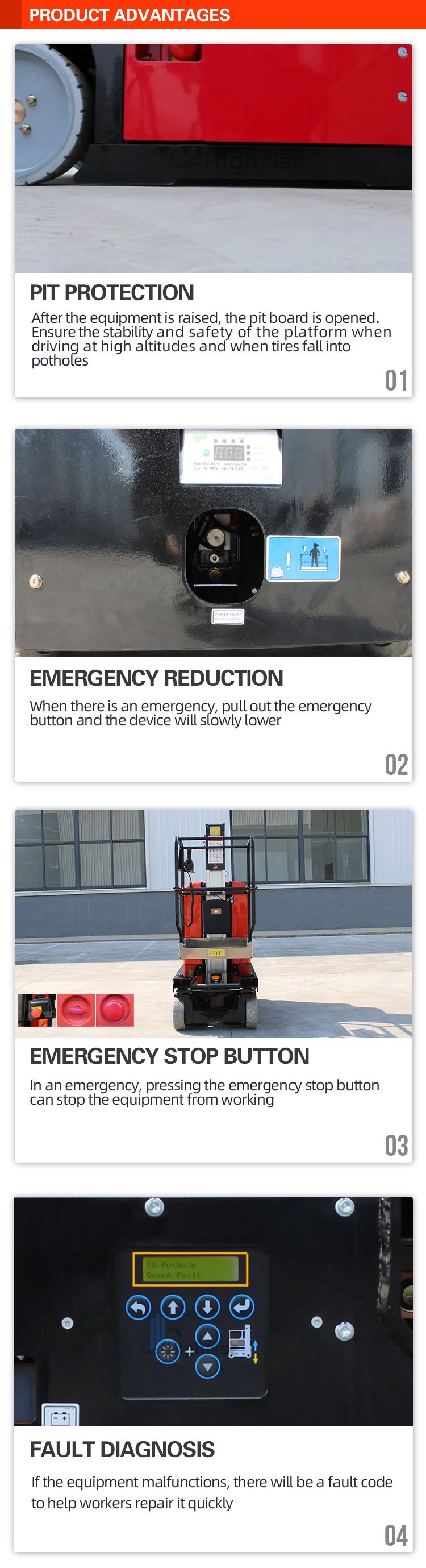

Safety and Operation Design

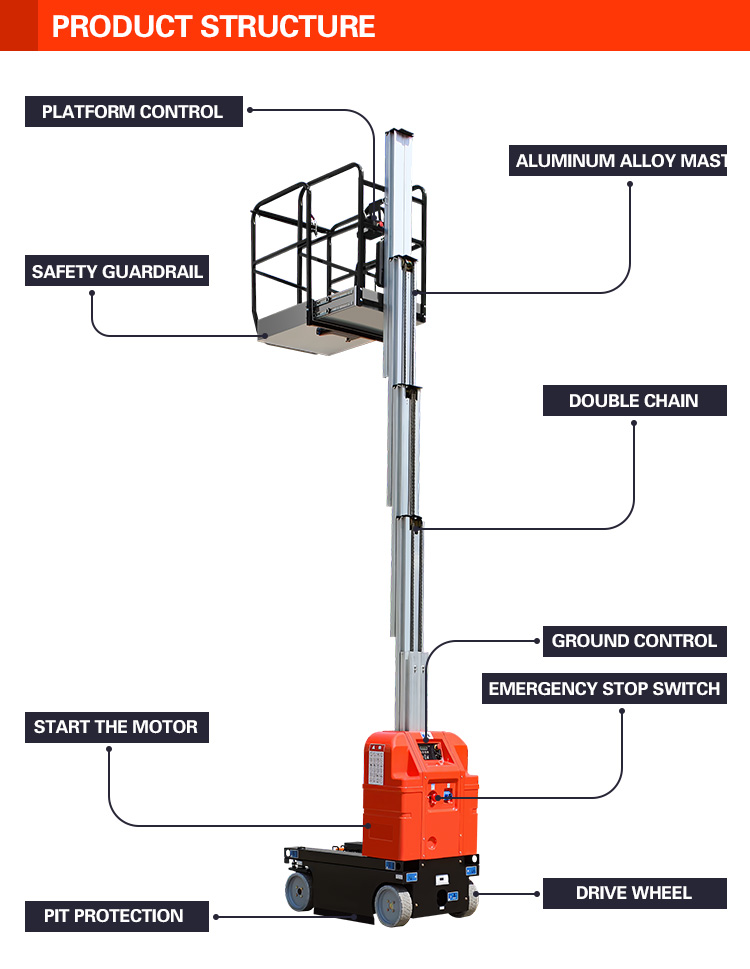

Basic Safety Features

Overload Protection: Hydraulic system cuts off lifting power and alarms when load exceeds 136kg (110% of rating).

Emergency Stop: Dual-control panels (ground/platform) feature emergency stop buttons for instant equipment locking.

Limit Protection: Mechanical limit switches at mast top/bottom prevent over-travel.

Outrigger Locking: Deployed outriggers lock via mechanical pins to avoid unexpected retraction during operation.

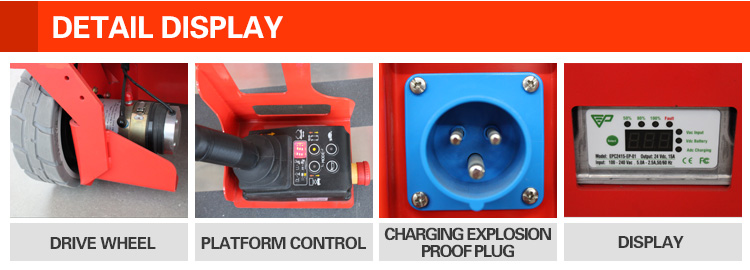

Operational Convenience

Dual Control: Supports platform panel and ground remote control (optional) for versatile scenarios.

Easy Transition: Universal wheels enable single-person short-distance movement; manual outrigger

deployment/retraction takes ~1 minute, enhancing multi-site efficiency.

Simple Maintenance: Open hydraulic system design allows easy replacement of filter elements, reducing daily maintenance costs.

Application Scenarios

Indoor Operations

Factory Equipment Maintenance: Suited for overhead pipeline and production line robotic arm servicing, with a narrow body navigating equipment gaps.

Commercial Facility Installation: Enables mall atrium lighting replacement and hotel lobby high-altitude decoration, fitting elevator transport.

Warehousing & Logistics: Facilitates high-bay racking inventory and warehouse ceiling ventilation cleaning with single-operator efficiency.

Outdoor Operations

Municipal Maintenance: DC version supports off-grid work for streetlight inspection and traffic sign replacement in urban areas.

Construction Sites: Meets temporary lifting needs for exterior wall painting and window installation on small projects, with outriggers stabilizing on mildly flat ground.

Special Scenarios: Ideal for narrow alley construction in old urban areas and mild-slope/soft-ground tasks (with pre-leveled support areas).

Core Advantages

Lightweight Design: Aluminum alloy reduces weight for easy transition, outperforming steel in corrosion resistance and service life.

Spatial Adaptability: Ultra-compact body and narrow outriggers break through traditional space limitations for confined-area operations.

Power Flexibility: Dual-power options cover indoor grid-connected and outdoor off-grid scenarios, minimizing power dependency.

Cost-Effectiveness: Standard safety features and simple maintenance make it ideal for SMEs and frequent light-duty aerial work, balancing performance and cost.

Ordering Information

Standard Configuration: AC power system, mechanical outriggers, dual-control panels, overload protection

Optional Accessories: DC power module, remote control, non-slip outrigger pads, rain cover

Certification: CE Mechanical Safety Certified (complies with EN 280:2013)

The ATWY1-10 delivers efficient, safe solutions for indoor/outdoor medium-high altitude work in narrow spaces, combining compact dimensions, reliable performance, and flexible configurations.

Russian

Russian