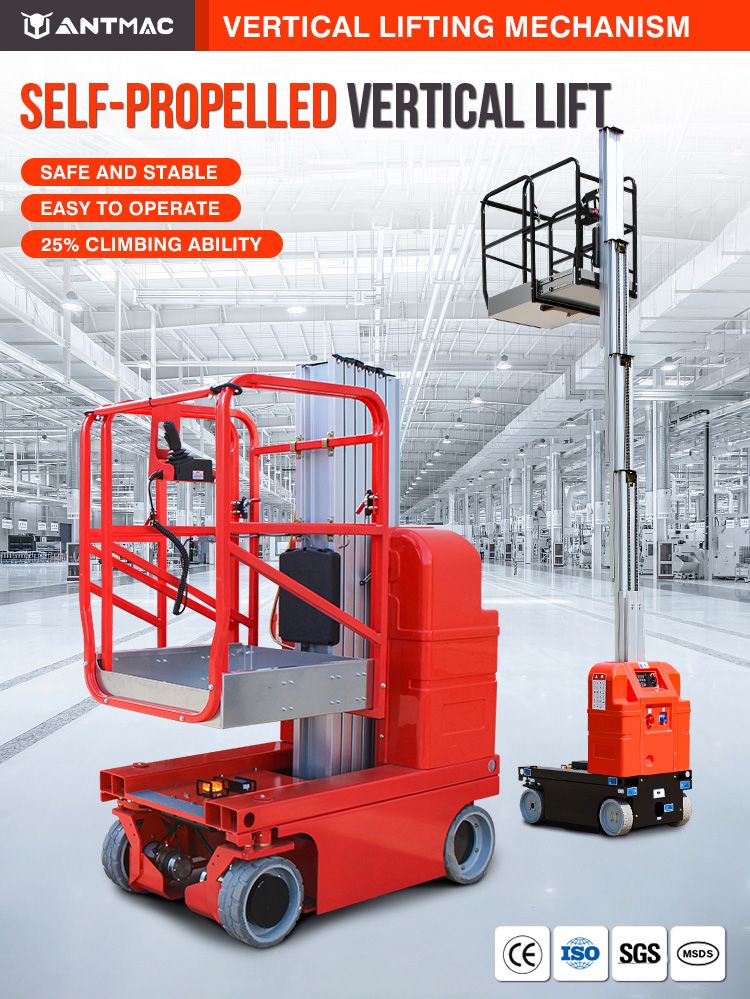

9.2 m Ultra-Stable Single-Column Outrigger Aluminum Platform for Aerial Work Factory Price

ATWY1-9 Single-Column Outrigger Mobile Aluminum Platform: Engineering-Grade Stability Solution for 9.2m Aerial Work

Ultra-High Altitude Single-Column Outrigger Architecture: Technological Breakthrough in High Strength and Lightweight Design

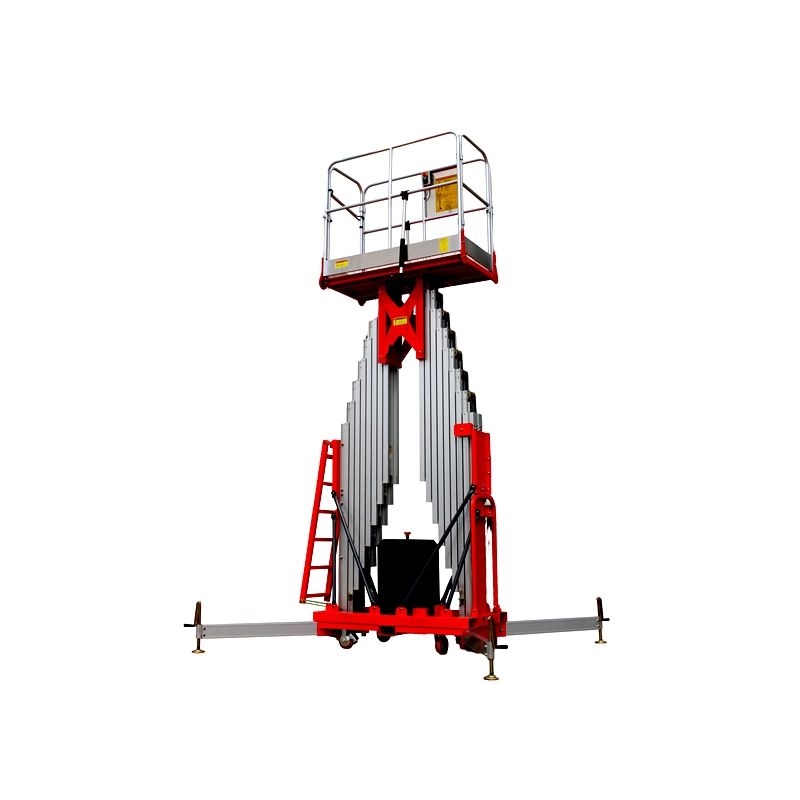

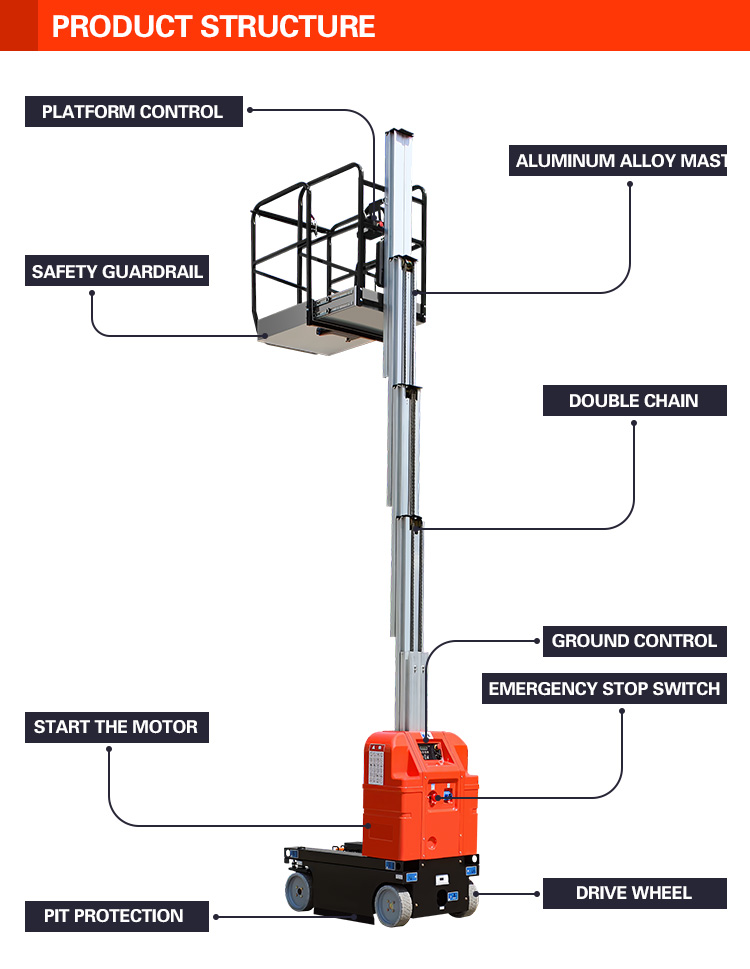

As the industry's first single-column aluminum platform exceeding 10 meters in working height, the ATWY1-9 employs aero-grade 6063-T6 aluminum extrusions, reconstructing the mast's mechanical structure through topological optimization design. It achieves a 11.2m maximum working height while maintaining an overall weight of 410kg (AC version)/460kg (DC version)—52% lighter than steel platforms at the same height. The compact 1.35m×0.76m body with a 1.99m retracted height fits vertically into standard freight elevators (car size ≥1.4m×1.1m). The deployed 2.1m×2.0m hydraulically locked outrigger support range, using ANSYS-optimized triangular stability structure, limits platform sway to ≤20mm under 7-level wind, overcoming the stability bottleneck of single-column platforms in ultra-high altitude operations. The 0.67m×0.66m non-slip surface features fall-arrest safety rope hooks and tool storage slots, providing professional-grade safety for single operators with precision instruments.

Intelligent Dual-Power Energy Management System: Full-Scene High-Efficiency Adaptation

The platform integrates a third-generation dual-power intelligent switching system, supporting quick interchange of AC/DC power modules:

Industrial-Grade AC System: Compatible with global 380V/220V/110V three-phase/single-phase power, a 1.5kW permanent magnet synchronous motor with vector control ensures 0.8m/s smooth lifting speed, ideal for continuous operations like automotive assembly plant overhead equipment maintenance or logistics warehouse high-bay racking. It runs 24/7 when plugged in.

Outdoor DC Solution (Optional): Upgraded to a 12V/120Ah lithium iron phosphate battery pack and 1.5kW brushless DC motor, supporting 8 hours of operation (6 lifting cycles/hour at full charge). With 24V/20A fast-charging technology, it recharges in 4 hours. The specially designed low-voltage protection circuit switches to energy-saving mode when battery level drops below 20%, ensuring continuity for off-grid scenarios like municipal bridge inspection or wind turbine tower maintenance.

The hydraulic system uses a German Rexroth load-sensing pump, with lifting speed ≤10 seconds/m (9.2m platform in ~92 seconds). Descent achieves 0.5m/s uniform buffering via an electronic proportional valve, 30% more efficient than traditional throttle valve control.

Seven-Layer Intelligent Safety Protection Network: Zero-Risk Assurance for Ultra-High Altitude Work

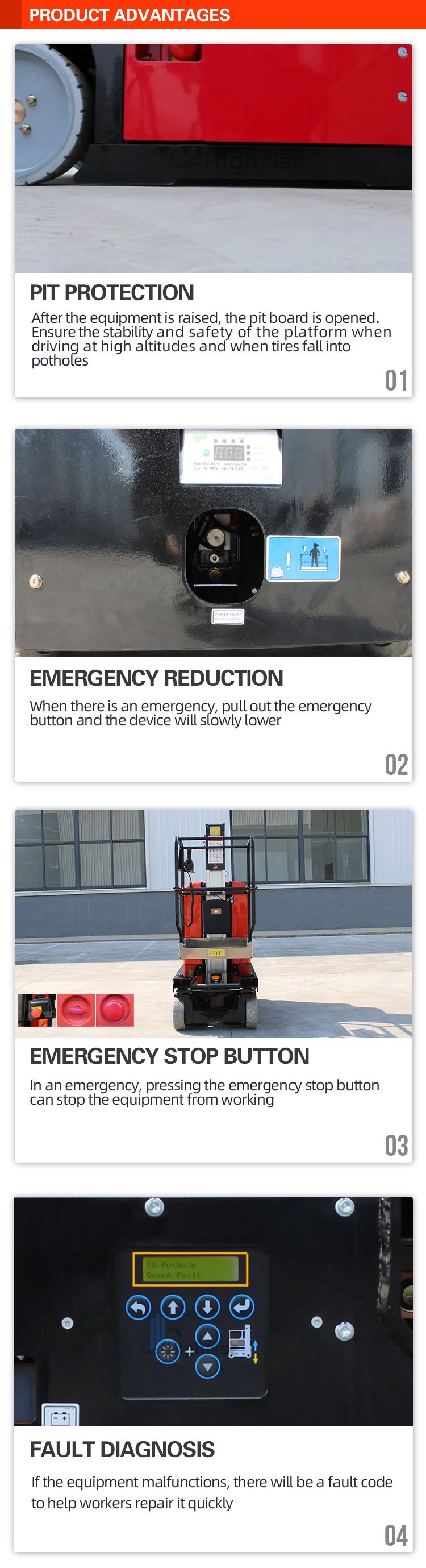

Structural Safety: Outriggers lock doubly with mechanical pins and hydraulic locks. An internal tilt sensor monitors the support surface in real time, triggering audio-visual alarms and disabling lifting when the tilt angle exceeds 2.5°. A pressure sensor interlocks with the PLC system to cut power if the load exceeds 165kg, preventing overload tipping.

Electrical Safety: Both control panels feature IP67 waterproof emergency stop buttons. A storage capacitor drives the emergency descent mechanism during power outages. A laser limiter at the mast top and ultrasonic sensor at the bottom ensure ±15mm precise positioning to avoid over-travel.

Material Safety: Aluminum components undergo T6 heat treatment for 265MPa tensile strength, passing 1,500-hour salt spray tests—suitable for corrosive environments like marine engineering or chemical plants. All welds undergo X-ray and dye-penetrant inspection for 10+ years of service life.

Hydraulic Safety: Integrated with German HBM pressure sensors and explosion-proof hoses, the system automatically relieves pressure over 18MPa. A accumulator drives the hydraulic lock to engage within 0.3 seconds in case of hose rupture.

Compliance Certification: Certified to CE-Machinery Directive 2006/42/EC and ISO 12100 mechanical safety standards, critical components (cylinders, outrigger joints) pass 3x rated load destructive tests, with an overall safety factor of 2.5x.

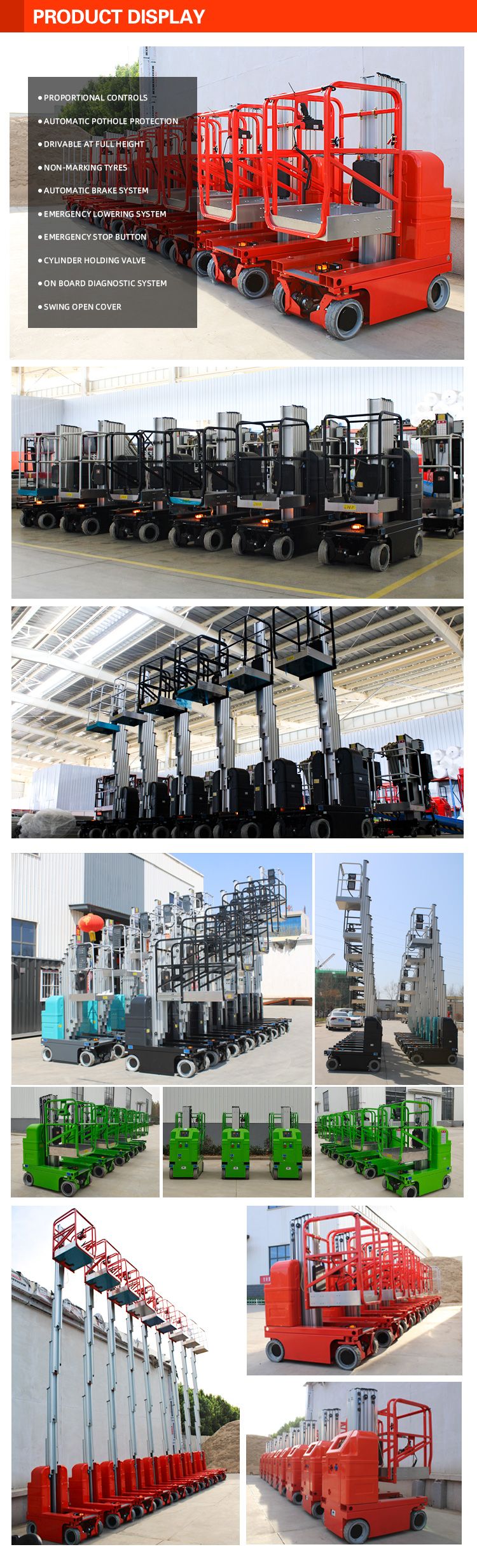

Full-Industry Ultra-High Altitude Solution: From Precision Workshops to Extreme Environments

Industrial Extreme Scenarios: 10m-level equipment debugging in aerospace workshops (0.76m width navigates equipment gaps), large data center ceiling cabling (1.99m retracted height fits machine room height, and petrochemical plant reactor top maintenance (aluminum anti-static spark properties).

Outdoor Complex Conditions: The DC version with off-road tires operates stably on 10° slopes or muddy terrain, suitable for wind turbine blade cleaning or high-voltage transmission tower maintenance. The 2.1m×2.0m support range with adjustable outrigger pads controls ground pressure below 0.5MPa on soft surfaces, protecting sensitive grounds like lawns or tiles.

Customized Expansion: Optional 200kg load upgrade kits, 360° rotating platforms, wireless remote systems, and -30℃ low-temperature hydraulic oil meet special environment needs like cold chain warehouses or Arctic research stations.

Intelligent Interaction and Low-Maintenance Design

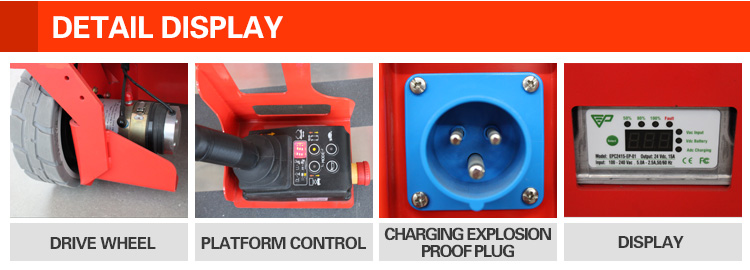

Ergonomics: A 7-inch color touchscreen integrates a fault diagnosis system, real-time displaying 12 parameters including height, tilt, and battery level. It supports Bluetooth connectivity to a mobile APP for remote equipment status monitoring—ideal for property management central dispatch.

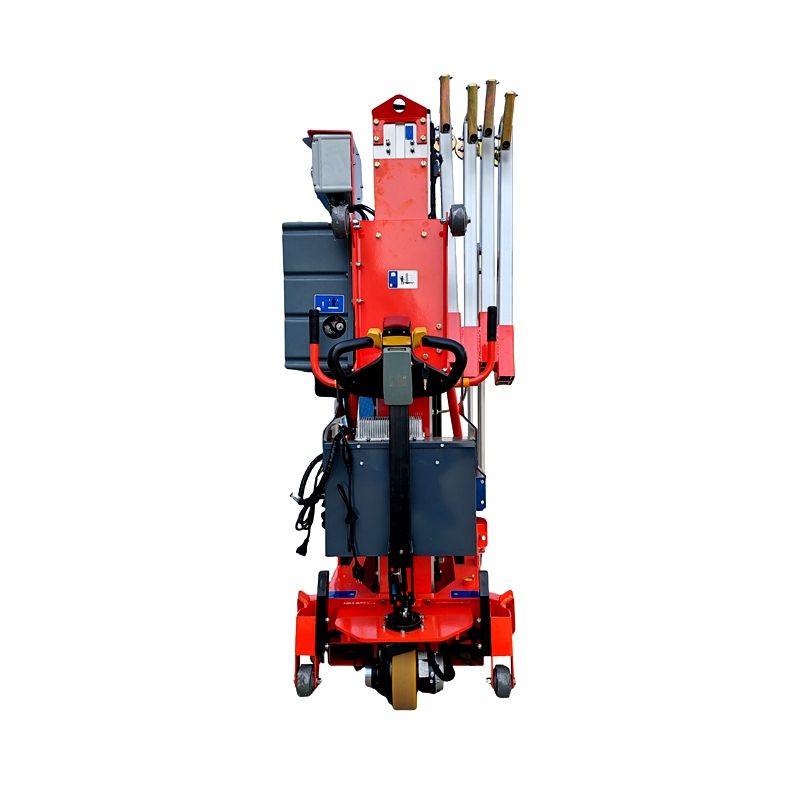

Rapid Transition: The body features electric traction wheels (optional), enabling 3km/h flat-ground movement via remote control. Hydraulic automatic outrigger deployment completes setup in 60 seconds with one button, 50% more efficient than traditional manual models.

Maintenance Innovation: Maintenance-free sealed bearings and self-cleaning hydraulic tanks extend service intervals to 1,000 hours. Modular power systems allow motor/battery replacement within 30 minutes, with annual maintenance costs only 25% of similar products.

Technical Innovation Highlights

The ATWY1-9 redefines the performance boundaries of single-column aluminum platforms with its 9.2m platform height, achieving breakthroughs in ultra-high altitude safety and efficiency through seven-layer safety protection, intelligent dual-power systems, and aero-grade lightweight design. Its original hydraulic automatic outrigger technology and fault early-warning system provide revolutionary solutions for ultra-high altitude work in manufacturing, energy, municipal, and other sectors, establishing itself as the benchmark equipment for 10m-class narrow-space aerial operations.

Russian

Russian