The Art of Warehouse Access: Articulating Booms – Your Go-To Aerial Access Solution for Up and Over Headaches

Why Old-School Tools Just Don’t Cut It for Warehouse High-Reach Jobs

Warehouses Are Built to Be Tricky – Here’s Why

Modern logistics hubs—especially online retail fulfillment centers and 3PL warehouses—are designed for maximum storage efficiency. With 12–15m racks, fast-moving conveyors, and AGV robots darting around, “up and over” repair tasks can be a nightmare. Imagine a ceiling light 10m above a conveyor or a sensor hidden behind a storage rack—you can’t just roll in traditional gear without disrupting everything.

Scaffolding? Total Waste of Time (and Space)

Scaffolding might seem reliable, but in 24/7 warehouses, it’s a time and space disaster. Setup and teardown take over 9 hours and eat up 3–4 meters of aisle space—completely blocking forklift movement. Even for a quick light repair, that’s massive downtime and lost revenue. Warehouses processing 5,000+ orders daily could lose tens of thousands just waiting for scaffolding.

Straight Boom Lifts: Too Clunky for Narrow Aisles

Straight booms—like traditional telescopic boom lift —are powerful but not ideal for warehouses. At over 2.5m wide, most can’t fit into narrow 2.2–2.5m aisles. And their single rigid arm can’t bend over conveyors or stacked pallets, forcing full repositioning just to reach a target point—costing valuable time and efficiency.

Ladders? Dangerous and Useless for Tall Racks

Ladders might seem like a quick fix, but climbing 6m or higher with tools in hand is risky and inefficient. Warehouse floors are hard concrete, forklifts are constantly moving, and ladders can’t safely reach 12–15m racks. It’s no wonder falls remain a top warehouse hazard.

Why Articulating Booms Are Warehouse Heroes

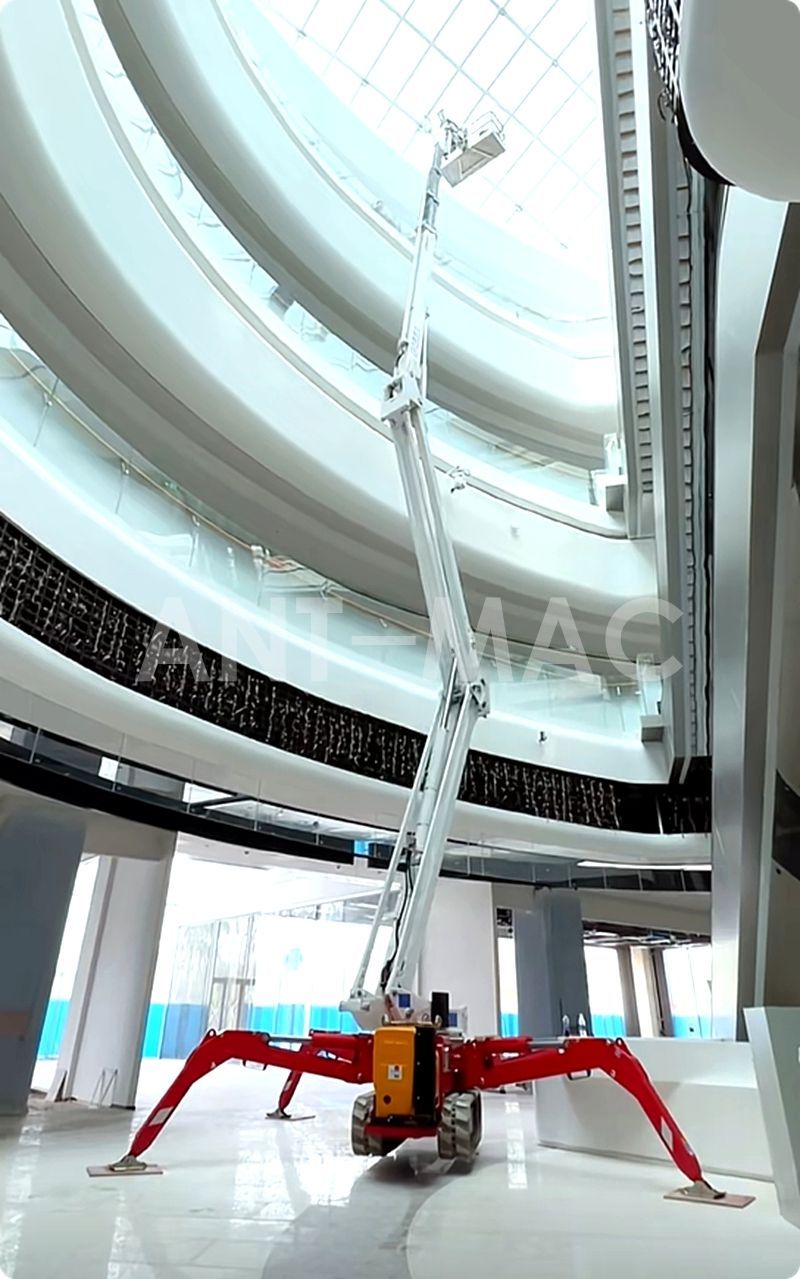

They Fit Where Others Can’t – and Bend Around Obstacles

Compact Design: Slips Through Aisles Like a Pro

Articulating boom lifts are purpose-built for tight warehouse environments. Most compact models are only 1.8–2m wide—perfect for 2.2–2.5m aisles—and still leave space for forklifts to pass. Unlike scaffolding or rigid booms, you can perform high-reach tasks without shutting down entire aisles or stopping operations.

Multi-Jointed Arms: The Secret to Beating Up and Over Challenges

The beauty of articulating booms lies in their multi-jointed arms, which can reach up to 18m high and bend 180° sideways. That means technicians can easily reach “up and over” conveyors, pallet stacks, or automated systems. Tasks that once required moving the whole machine are now completed in one smooth motion—boosting safety and speed.

Real-World Win: Houston Fulfillment Center’s 50-Minute Fix

A major Houston e-commerce hub had a 12m-tall light go out above a conveyor. Instead of scaffolding, they used a compact articulating boom lift, navigated through a 2.3m aisle, and reached over the conveyor. The job was done in under an hour—while forklifts kept running. Scaffolding would’ve taken 8+ hours.

Fast to Set Up, No Big Disruptions

Ready to Go in 10–15 Minutes (vs. Hours for Scaffolding)

Warehouses need uptime—and articulating booms deliver it. With quick setup by a single operator, these lifts are ready in 10–15 minutes. No teams, no wasted hours, no work stoppage. Whether it’s fixing a ceiling light or inspecting sensors, you can act instantly without waiting for downtime.

Electric-Powered: Quiet and Clean for Indoor Work

Electric-powered towable boom lifts and compact spider cranes are perfect for indoor use. They run quietly (under 65 decibels) and produce zero emissions, so they can work safely beside inventory and personnel—no fumes, no noise complaints, and no ventilation concerns.

Routine Inspections? 3x Faster Than Ladders

The same Houston center later adopted articulating booms for regular rack inspections. Technicians zipped between aisles, bending over rack beams to check for damage. Routine inspections became three times faster than using ladders, improving both safety and productivity.

Pro Tips to Get the Most Out of Your Articulating Boom

Pick the Right Boom for Your Warehouse

Map your aisles before choosing a lift. For aisles 2–2.5m wide, pick a model under 1.8m wide. Need to reach tall ceilings? Choose a 15–18m truck-mounted boom lift or articulating model. The right fit saves you hours of frustration and keeps projects running smoothly.

Schedule Work During Slow Hours (Even Though You Don’t Have To)

While articulating booms are efficient enough to use during busy shifts, working during off-peak hours (like 11 PM–5 AM) makes things even smoother. Less traffic, faster workflow, zero delays.

Real Example: Walmart Atlanta Saved $8K in Labor

A Walmart distribution hub in Atlanta used a 1.7m-wide articulating boom for late-night rack light repairs. The job took 2 hours instead of 4.5—cutting labor costs by $8K and keeping daytime operations uninterrupted.

Safety Bonus: Automatic Leveling = No Dropped Tools

Most modern articulating booms feature automatic leveling systems, keeping platforms stable within 2 degrees on uneven floors. That means no dropped tools, no damaged conveyors, and no safety scares—ideal for busy warehouse floors.

The Bottom Line

As warehouses grow taller and more automated, flexible aerial solutions like articulating boom lifts and compact electric scissor lifts are redefining how high-reach work gets done. They fit through narrow aisles, set up in minutes, and keep operations running safely and efficiently.

The future of warehouse maintenance isn’t about climbing higher—it’s about working smarter, safer, and faster. And Ant’s high-performance aerial work platforms are engineered to make that possible.

Explore the full range of aerial access solutions at Ant Machinery’s official website or contact us for expert guidance on choosing the right lift for your facility.

Data Speaks: Antmac's After-Sa

Data Speaks: Antmac's After-Sa

Industry Trendsetter: Antmac's

Industry Trendsetter: Antmac's

Antmac Leads Industry Upgrade

Antmac Leads Industry Upgrade

Beyond Lifting: Redefining Con

Beyond Lifting: Redefining Con

Russian

Russian