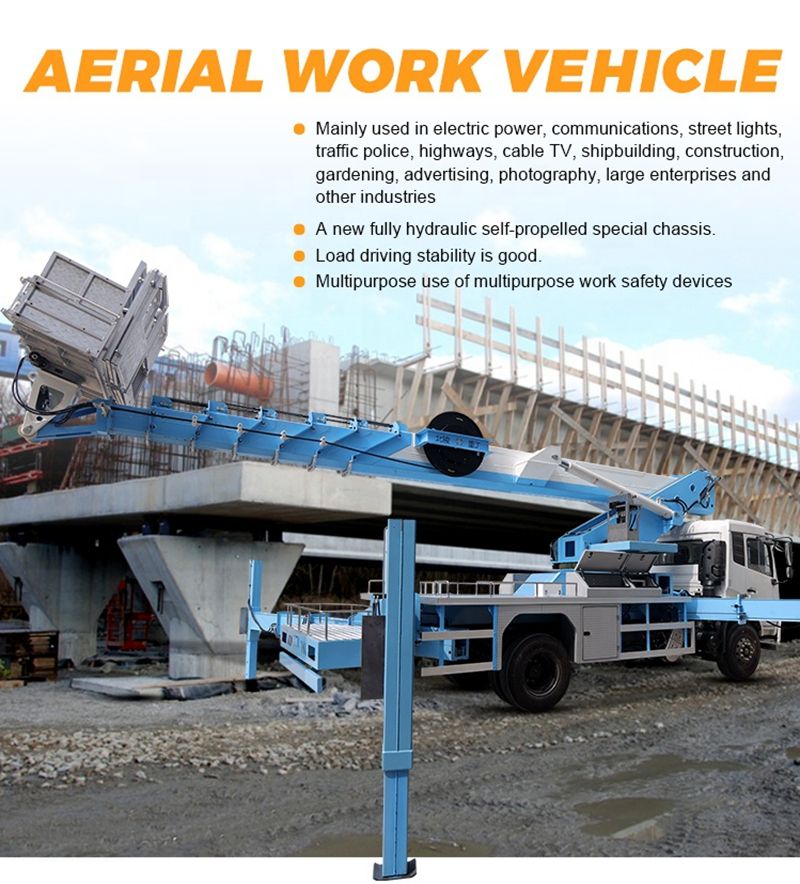

46 m Industrial Arm Type Aerial Work Platform For Sale

DETAIL PRESENTATION

PRODUCT SELLING POINTS

PRODUCT APPLICATIONS

PRODUCT MANUFACTURING PROCESS

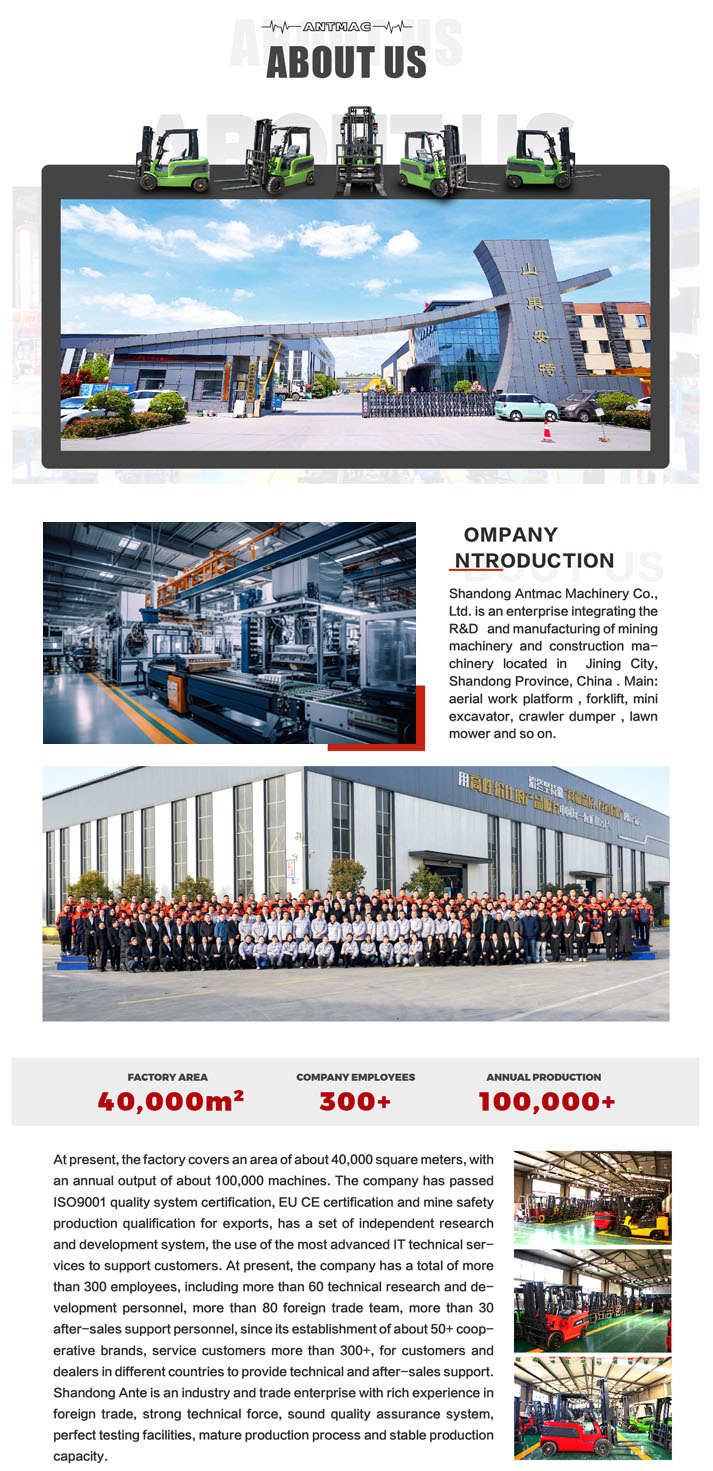

ABOUT US

PACKAGING AND TRANSPORT

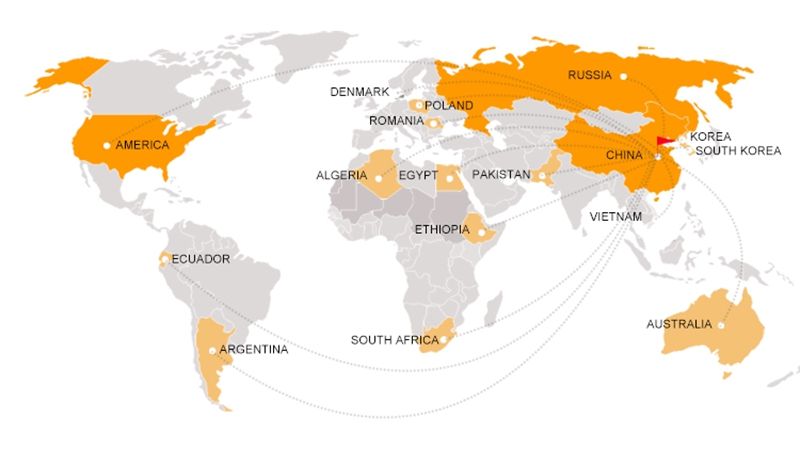

MARKETING NETWORK

FAQ

46m Industrial-Grade Boom Aerial Work Vehicle Product Introduction

I. Vehicle Basic Parameters

1. Dimensions Specifications

The vehicle adopts a compact and flexible layout design:

Total length: 9680mm, enabling free navigation between urban roads and construction sites.

Total width: 2550mm, fully complying with highway transportation standards for excellent road passability.

Total height: 3800mm, easily adapting to height limits of most urban bridges and tunnels.

Wheelbase: 4500mm, front overhang: 1430mm, rear overhang: 2920mm. The scientific wheelbase and overhang ratio balances the center of gravity for stable driving.

Rear extension: 830mm, providing auxiliary support for material hoisting.

2. Mass and Load Bearing

Cab: Flat-top semi-row design, spacious and comfortable, accommodating 3 passengers.

Gross vehicle mass: 18000kg, complying with highway load standards, with a high-strength chassis for reliable operation in complex conditions.

II. Driving Performance Parameters

Maximum speed: 80km/h, ensuring efficient site transfers while prioritizing road safety.

Chassis: DFH1180EX8, equipped with B6.2NS6B230 National VI engine, 4×2 drive form, excellent passability for various terrains.

III. Core Operation Technical Parameters

1. High-Altitude Operation Capability

Work platform rated load: 300kg, supporting 2-3 operators with tools.

Seven-section synchronous telescopic boom: Made of imported 4-5 grade high-strength steel, hexagonal cross-section for superior bending resistance.

Maximum working height: 46m, with a 39m amplitude at 46m height; at maximum amplitude of 22m, working height remains 6m, covering large areas.

2. Outriggers and Stability

Outriggers: X-type high-strength structure, longitudinal span 7450mm, transverse front 7570mm/rear 8100mm, built with Baosteel 5-6mm high-strength plates.

Dual hydraulic locks and level detection system resist tipping risks.

Outrigger deployment/retraction time: ≥80s, with detection switches, alarm indicators, and buzzers for safe operation.

3. Motion Performance

Slewing speed: ≥60s/rev, 360° continuous rotation;

Platform lifting time: ≥120s, lowering time: ≥95s, ensuring smooth operation.

Basket: Static hydraulic auto-leveling, electric 360° rotation, two safety belts, carbon steel frame, reliable safety under ≤300kg load.

IV. Core Structure and Configurations

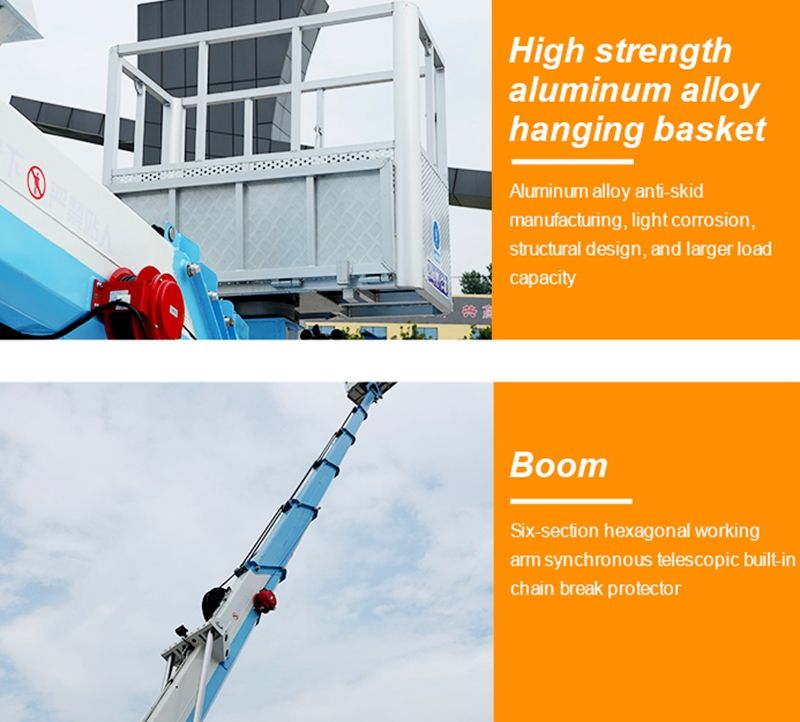

1. Boom System

Seven-section synchronous telescopic boom: Imported high-strength steel welding, hexagonal cross-section, luffing angle 0°-78° (relative to horizontal).

Dual-cylinder luffing with limit indicators prevents over-limit operation.

2. Hydraulic and Operation System

Hydraulic system: 200L tank, 50ml/r gear pump, 20MPa working pressure.

Electro-hydraulic proportional valve block with manual emergency button; 13 cylinders with double-acting balance valves and hydraulic locks.

Operation modes: Turntable cab (with comfortable seat) and basket wireless remote control, supporting remote engine start/stop and throttle control, interlock design to avoid misoperation.

3. Chassis and Details

Body: High-quality carbon steel and aluminum alloy, double-layer 25mm non-slip embossed aluminum plate, two toolboxes on each side, complete side/rear protection.

Turntable: Imported high-strength steel welding, single-row four-point contact ball slewing bearing, dual planetary reducers and hydraulic motors for smooth rotation.

Paint: Famous brand, durable color; clear sign compliant with international safety standards.

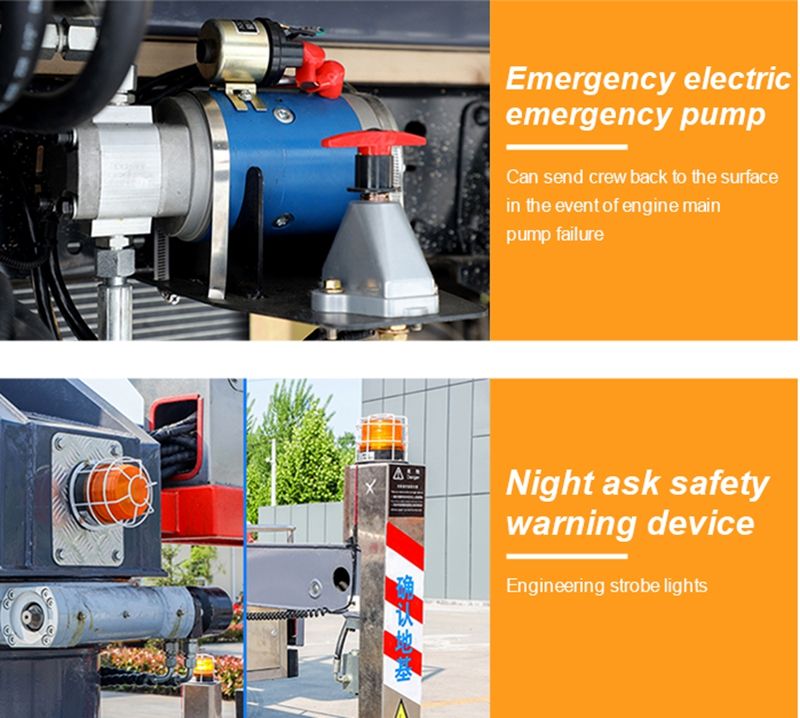

V. Safety and Reliability Design

Outriggers: Level meters and four yellow strobe lights, real-time monitoring with audio-visual alarms for anomalies.

Electric emergency pump: Manually retracts the boom in hydraulic failures for safe evacuation.

Key components (boom, outriggers) use high-strength steel with non-destructive testing welding for long-life and safety.

VI. Application Scenarios

Suitable for high-rise exterior construction, municipal streetlight maintenance, billboard installation, power line repair, factory equipment maintenance, etc. Excels in high-height and large-amplitude projects, combining fast urban transfer and complex terrain adaptability—ideal for construction, municipal, and power industries.

With a core competitiveness of 46m working height, this aerial work vehicle integrates high-strength design, intelligent operation, and multiple safety protections, reaching industry-leading efficiency and reliability for all high-altitude projects.

Russian

Russian