The Ultimate Balance Between Efficiency and Cost: In-depth Analysis of the Selection Logic of Electric vs. Fuel-Powered Forklifts, and ANTMAC's High- Value Answer

After a medium-sized logistics warehouse replaced 10 fuel-powered forklifts with ANTMAC electric forklifts, its total annual operating costs decreased by 38%, including a 62% reduction in fuel and maintenance costs. The reduction in equipment noise even improved the efficiency of internal warehouse communication by 15%.

In the global materials handling industry, the choice between electric and fuel-powered forklifts has transcended a simple "power preference" and evolved into a sophisticated calculation involving total cost of ownership (TCO), operational efficiency, environmental regulations, and long-term strategy . Industry analysis suggests that in scenarios with an average daily shift of 8 hours or more, the economic advantages of electric forklifts will become clearly apparent within 2-3 years.

For decision-makers, this is not an either-or choice, but rather an equation for finding the optimal solution based on their own operational scenarios. Understanding the core differences between electric (electric-powered) and gasoline (gasoline-powered) vehicles is the first step in making informed investments.

I. The Deep Game of Cost Structure: Purchase Price vs. Total Cost of Ownership

When making a choice, price is often the primary consideration. Fuel-powered forklifts typically have lower initial purchase costs , which constitutes their most immediate appeal. However, the real costs are hidden over an operating cycle that can last for years, or even decades.

The return on investment (ROI) model for electric forklifts is characterized by "high initial investment and low long-term costs." Its core advantage lies in its extremely low energy consumption costs . Taking ANTMAC lithium-ion electric forklifts as an example, their energy costs are typically only 20%-30% of those of fuel-powered forklifts with equivalent workloads. Considering a warehouse operating on a single shift for 2000 hours per year, the annual savings from the price difference between fuel and electricity alone are considerable.

More importantly, there is a significant difference in maintenance costs . The power structure (motor, electronic control) of electric forklifts is far simpler than that of internal combustion engines (internal combustion engine, gearbox, transmission system), with a substantial reduction in moving parts. This eliminates the hassle and expense of regular maintenance and repairs such as changing oil, filters, and spark plugs. Overall, the total maintenance cost of electric forklifts is typically 40%-60% lower than that of internal combustion engine forklifts.

Therefore, the decision-making process should shift from "purchase price" to "total cost of ownership." For scenarios with high usage intensity and long cycles, electric forklifts are often a more economically rational choice.

II. Scenario-based adaptation of performance characteristics: strength, endurance, and environment

Performance is not a competition of a single dimension, but rather a match between different characteristics and specific scenarios.

Power and Continuous Operation Capability : Traditionally, fuel-powered forklifts have advantages in extreme heavy loads and long-term high-intensity continuous operation (such as 24-hour operation in ports and steel mills), offering rapid refueling and strong power output. However, modern advanced electric forklifts, especially models equipped with high-performance permanent magnet synchronous motors, offer high instantaneous torque and excellent acceleration performance, resulting in higher operating efficiency and more agile response in indoor loading and unloading and short-distance frequent reversing conditions. ANTMAC's electric forklift series, through its advanced electronic control system, achieves smoother and more precise operation, greatly improving the safety and efficiency of cargo stacking.

Environmental Impact and Applicable Locations : This is where electric forklifts have a decisive advantage. Their zero-emission characteristic makes them a mandatory choice for industries with stringent air quality requirements, such as food, pharmaceuticals, and electronics. Simultaneously, their low noise level not only improves the operator's working environment but also enables nighttime operations or operations in noise-sensitive areas (such as warehouses near residential areas). In contrast, the emissions and noise of fuel-powered forklifts strictly limit them to well-ventilated outdoor areas or specific industrial zones.

The key to selection lies in a clear definition of your primary operating scenario: Indoor or outdoor? Light-load, high-frequency or heavy-load, continuous? Are there any restrictions on the environment and noise?

III. Technological Evolution and Basic Support: The Lithium Battery Revolution and Infrastructure

Technological advancements are rapidly rewriting the rules of the game. Traditional lead-acid battery forklifts suffer from drawbacks such as long charging times, the need for dedicated charging rooms, and cumbersome battery maintenance. The maturity and widespread adoption of lithium-ion battery technology , however , have almost perfectly solved these problems.

Advanced electric forklifts, exemplified by ANTMAC, utilize lithium batteries that support random charging (recharging during breaks), eliminating the need for battery replacements and avoiding the maintenance and acid risks associated with lead-acid batteries. These batteries boast high charging efficiency, a lifespan 3-4 times longer than lead-acid batteries, and slow performance degradation throughout their lifespan. This represents a significant leap forward in the durability and convenience of electric forklifts.

Of course, choosing electrification also requires assessing a company's infrastructure , such as the availability of convenient charging facilities. However, this is usually a one-time, planned investment, with long-term benefits far outweighing the initial cost of the upgrade.

IV. ANTMAC's Integrated Intelligence: More Than Just Products, It Offers Solutions

In response to the real challenges faced by customers, ANTMAC's role is not simply to sell a particular type of forklift, but to become a value partner for customers , providing customized solutions based on deep insights.

① A precise product matrix tailored to specific scenarios : We offer a full range of electric forklifts , from those equipped with cutting-edge lithium batteries to high-performance fuel-powered forklifts suitable for the most demanding outdoor conditions . For example, our ANTMAC G series lithium-ion electric forklifts are designed for high-intensity, multi-shift warehouse logistics, and a 1.5-hour fast charge is enough for a shift; while the XT series reinforced fuel-powered forklifts provide reliable power for harsh environments such as heavy industry and wood processing.

② Professional TCO analysis service : In the early stages of sales, our engineers can tailor a detailed total cost of ownership analysis report for customers based on the operational data provided by the customers (daily working hours, handling volume, peak load, etc.), which will intuitively present the cost composition and differences of different power solutions over 5-8 years, making investment decisions clear.

③ Future-Oriented Technology Path : We actively guide our clients to focus on long-term industry trends—increasingly stringent environmental regulations, fluctuating energy costs, and growing demand for automation and intelligentization. Choosing ANTMAC electric forklifts not only addresses current needs but also provides a more compatible technology platform for sustainable development and future upgrades (such as integration with fleet management systems and data-driven operations and maintenance).

V. Customer Testimonials: The Value Leap from Hesitation to Conviction

A large auto parts manufacturer in Southeast Asia had long used fuel-powered forklifts. Faced with pressure to upgrade the factory's environmental protection standards and control costs, they had doubts about electric steering: Was the power sufficient? Could peak production capacity be guaranteed? After the ANTMAC team arrived, they did not immediately promote their products, but instead conducted a month-long free data-driven test using three lithium-ion electric forklifts on their busiest production line .

The test report showed that, under the same workload, the electric forklift not only fully met the power requirements, but its precision and stability also reduced the loss rate of handling precision parts; by quickly replenishing power during lunch breaks and work breaks, it fully met the requirements for continuous operation; and monthly energy costs decreased by 72%. Based on this solid data, the factory ultimately decided to replace all forty-plus forklifts with ANTMAC lithium-ion battery models in batches. Its operations director stated, "ANTMAC has shown us with facts that this is not just a replacement of equipment, but a comprehensive upgrade of operational efficiency."

The choice between electric and fuel-powered forklifts is deeply rooted in your unique operating environment. It's about numbers, regulations, and most importantly, your vision of the workplace of the future.

ANTMAC believes that the best choice is neither the most expensive nor the cheapest, but the most suitable and time-tested . We are committed to helping every client see through the fog and find the key to efficient, low-carbon, and low-cost operations through professional products and consulting, making every move a step in the right direction.

Dissecting the "Internal

Dissecting the "Internal

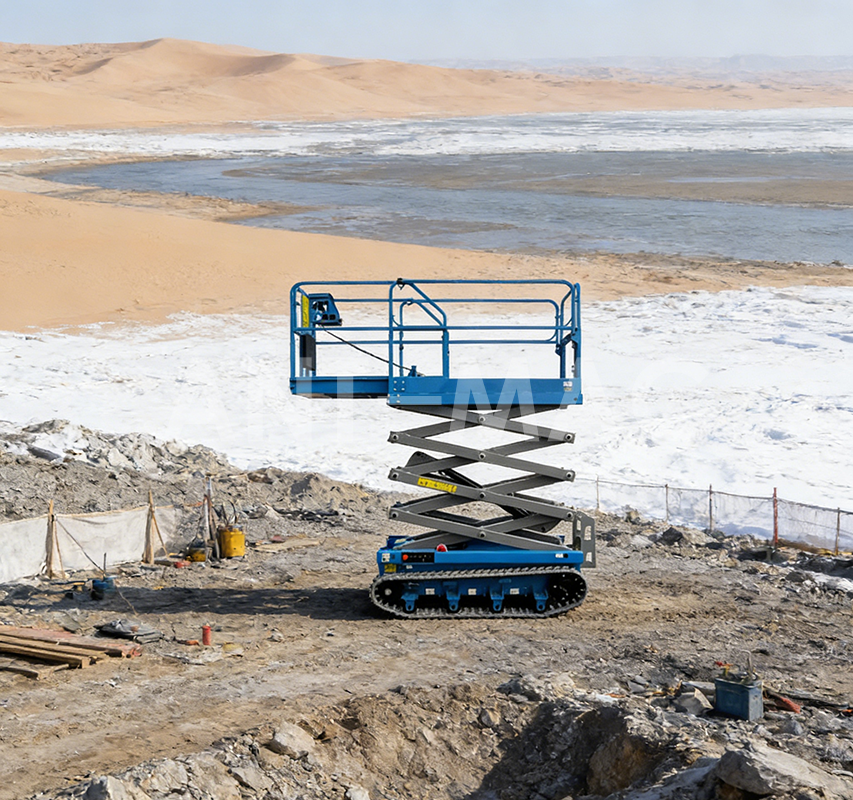

Foreseeing 2026: When Scissor

Foreseeing 2026: When Scissor

The Ultimate Balance Between E

The Ultimate Balance Between E

Engineering Decoding: The Art

Engineering Decoding: The Art

Russian

Russian