Foreseeing 2026: When Scissor Lift Platforms Evolve from "Lifting Tools" to "Intelligent Material Handling Hubs"

In early 2025, in the Asia No. 1 smart warehouse of a global e-commerce company, a set of scissor lift aerial work platforms equipped with autonomous navigation and intelligent recognition systems completed the periodic inventory and replenishment guidance of 100,000 warehouse shelves without human intervention, improving the efficiency of traditional manual inventory by 300% and bringing the inventory accuracy rate infinitely close to 100%.

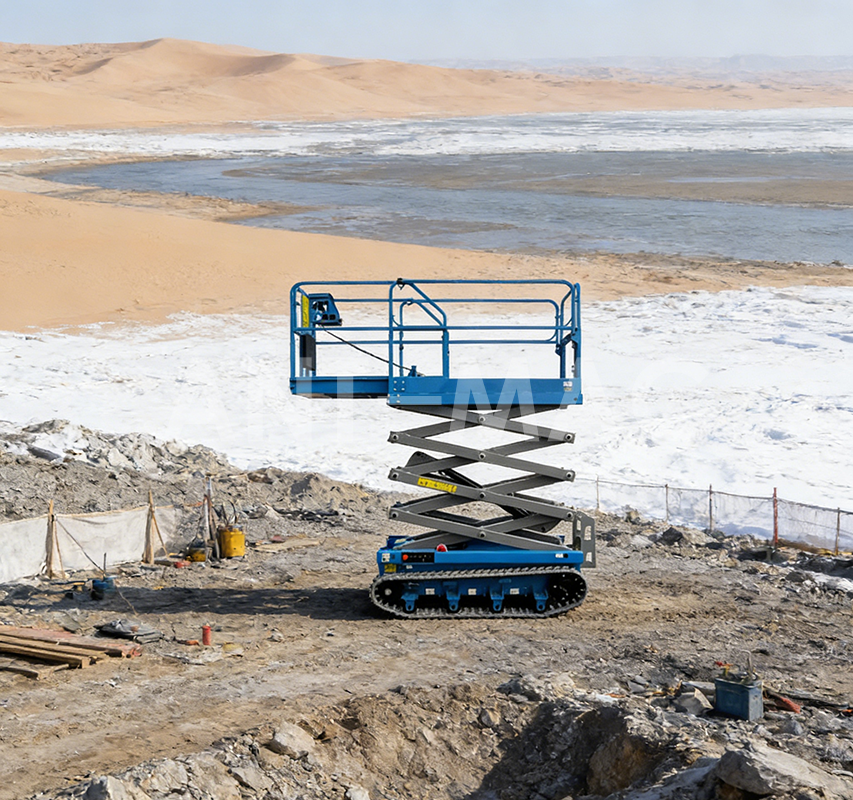

In the material handling industry, the competition for efficiency has extended from the ground to the air. Traditional scissor lift aerial work platforms are rapidly shedding their simple "vertical lifting" label. By 2026, the core driver of this category's evolution will no longer be simply lifting height or load capacity, but rather its deep integration capabilities as a "smart logistics node" and "data interaction terminal . "

The paradigm for material handling is shifting: from "people finding goods and moving goods" to " data-driven equipment, equipment serving processes ." Scissor lift platforms, with their inherent stability, large load-bearing capacity, and broad indoor adaptability, will become the most crucial aerial support in this transformation.

I. First Trend: The Intelligent Leap from "Manual Operation" to "Autonomous Collaboration"

By 2026, scissor lift platforms in material handling scenarios will generally be equipped with "limited-scenario autonomous driving" functionality. This does not replace operators, but rather frees them from repetitive and inefficient driving movements, allowing them to focus on higher-value loading, picking, and inspection tasks.

Technology Preview : By integrating LiDAR, vision cameras, and high-precision maps, the platform can autonomously navigate, avoid obstacles, and stop at designated points within warehouse aisles. Operators simply need to select the target shelving area on their terminal, and the platform will automatically plan the optimal path to reach it smoothly. Once connected to a Warehouse Management System (WMS), the platform can directly receive instructions and proceed to the next precise storage location requiring operation, achieving streamlined collaboration with conveyor belts and AGVs (Automated Guided Vehicles).

Value proposition : This will completely eliminate operator fatigue from traveling back and forth and human navigation errors, transforming "waiting people on the platform" into "service providers on the platform," and is expected to improve overall operational efficiency by more than 25%. Antmac's "Follow-Me" intelligent vehicle-following system , currently under development , is a pioneering practice of this trend.

II. Second Trend: Data Evolution from "Bearing Platform" to "Sensing Terminal"

The scissor lift platform of the future will be a powerful mobile data acquisition station in itself. Its working platform will integrate multiple sensors, no longer passively carrying loads, but actively sensing the status of cargo, environment, and mission.

Technology Preview : The platform's guardrails will be equipped with RFID readers that automatically scan shelf labels during lifting and lowering, enabling real-time inventory checks. The integrated 3D vision system can automatically identify pallet stacking status, the integrity of goods packaging, and even measure goods dimensions, transmitting data back to the central system in real time. Furthermore, the platform can monitor surrounding personnel density and air quality (such as dust concentration), becoming a dynamic monitoring point for warehouse environment and safety.

Value proposition : This enables data collection and auditing to be completed simultaneously with every high-altitude operation, achieving "dynamic visualization" of material information. For modern logistics centers pursuing lean management, this means an equipment investment that simultaneously solves three major pain points: high-altitude storage and retrieval, real-time inventory data updates, and on-site safety monitoring.

III. The Third Trend: From "Electric Driven" to the Green Role of "Energy Network Node"

Pure electric drive has become the absolute mainstream for indoor scissor lift platforms. The trend in 2026 is that the platform will be deeply integrated into the building energy network, transforming from an "energy consumption unit" into a dispatchable "distributed energy storage node".

Technology Preview : A platform equipped with high-capacity, fast-charging lithium batteries can charge during off-peak hours (such as at night) and, during daytime work breaks, even during peak grid hours, supply power back to the local grid via vehicle-to-grid (V2G) technology , participating in energy dispatch. Its battery system will become part of the warehouse microgrid, improving the overall facility's renewable energy utilization rate and power stability.

Value proposition : This significantly reduces carbon emissions throughout the equipment's lifecycle and transforms energy costs from an "expense" into potential "revenue" or "regulatory resource." For companies with a large number of electric vehicles, their fleet as a whole becomes a virtual power plant, highlighting the social responsibility and sustainable development leadership of leading companies.

IV. The Fourth Trend: From "Standard Equipment" to "Modular as a Service" – A Form Restructuring

Faced with highly diverse material handling needs (from electronic components to automotive parts), the delivery model of scissor lift platforms will become more flexible in the future. Modular design and "hardware as a service" subscription models may emerge.

Technical Preview : The platform will primarily use standardized interfaces, and the work platform can be quickly replaced with assembly modules equipped with robotic arms, intelligent picking modules with weighing and barcode scanning functions, or precision handling modules with protective features, as needed. Customers may no longer need to purchase equipment upfront; instead, they can subscribe to a complete service package including equipment, maintenance, and upgrades based on project timelines and specific functional requirements.

Value proposition : This significantly lowers the barriers and costs for customers to handle non-standard, temporary high-altitude handling tasks, achieving "what you need is what you use." Manufacturers, through continuous service and data connectivity, establish long-term partnerships with customers and transform from simple equipment vendors into continuous providers of productivity solutions.

V. The Fifth Trend: From "Safety Protection" to "Proactive Intervention" for Worry-Free Security

Safety is always the bottom line, but the goal of future safety systems is "zero proactive intervention." The platform in 2026 will have a stronger understanding of the environment and the ability to predict risks, achieving a leap from passive alarms to proactive prevention.

Technical Preview : Based on the aforementioned sensor fusion, the platform can construct a dynamic digital twin of its surrounding environment. The system can predict potential intrusion paths by personnel, identify collision risks from high-altitude obstacles, and decelerate or lock actions in advance. By monitoring the stability of the operator's posture (using the platform floor pressure distribution map), it can provide early warnings of fatigue or imbalance risks and intervene "softly" through methods such as a smooth, automatic descent.

Value proposition : This creates a near-absolutely safe working environment, significantly reducing accident rates and the resulting downtime losses and insurance costs. It transforms safety from a "responsibility" into a tangible "experience" and "guarantee," becoming one of the brand's core competitive advantages.

Investing in a scissor lift aerial work platform designed for 2026 is far more than just acquiring a more efficient lifting device. It essentially embeds an evolving, connectable, and sensing intelligent aerial node into your company's material handling system .

Antmac is strategically positioning itself along these trends. Our next-generation scissor lift platform was designed from the outset with interfaces reserved for intelligent modules, an architecture built for data connectivity, and the groundwork laid for energy interconnectivity. We invite visionary customers to explore the future with us, going beyond simply purchasing a product; we are proactively deploying a future-oriented productivity solution.

In the planning of a "lighthouse factory" for automotive parts in Germany, its future logistics center requires that the status of all equipment be integrated into a digital twin system in real time. Antmac 's scissor lift platform solution, with its comprehensive data interfaces and self-aware status capabilities, was successfully selected. The factory's logistics director commented, "What we need is not just lifting equipment, but intelligent nodes that can 'talk,' 'report,' and 'self-reflect.' It brings us one step closer to truly transparent and adaptive logistics."

Dissecting the "Internal

Dissecting the "Internal

Foreseeing 2026: When Scissor

Foreseeing 2026: When Scissor

The Ultimate Balance Between E

The Ultimate Balance Between E

Engineering Decoding: The Art

Engineering Decoding: The Art

Russian

Russian