Dissecting the "Internal Organs" of a Modern Electric Forklift: From Universal Construction to ANTMAC's Engineering Breakthroughs

During an equipment audit of a cold chain logistics company, it was discovered that the overall efficiency of a certain brand of electric forklift decreased by 40% after working continuously for 2 hours in an environment of -5℃. In contrast, after comparative testing under the same working conditions, ANTMAC's equivalent model maintained an efficiency rate of over 92%. This 15% difference is precisely the "technological gap" hidden in the structure and components.

An electric forklift is far more than a simple combination of "battery + motor + chassis". It is a highly integrated and sophisticated system whose performance, reliability, and total cost of ownership (TCO) are determined as early as when engineers draw up the blueprints for each component.

Understanding its structure is not just about satisfying technical curiosity, but also about having a keen eye to see through marketing rhetoric and discern core value in purchasing decisions.

I. Heart and Muscles: The Three-Electric System Determines the Performance Ceiling

The core power source of an electric forklift is the "three-electric system," consisting of a motor, electronic control unit, and battery . This directly determines the forklift's power, speed, range, and energy efficiency.

① Motors (Drive and Pump Motors) : Like the heart and muscles of the human body. ANTMAC uses high-frequency permanent magnet synchronous motors for the drive system, which are 8-15% more efficient than traditional asynchronous motors. This means less power consumption and stronger continuous output capability. Simultaneously, we equip the hydraulic system (responsible for gantry lifting and tilting) with independent high-efficiency permanent magnet pump motors , achieving precise on-demand power supply and avoiding the energy waste of "overpowered motors for small loads" in traditional single-motor drive solutions.

② Electrical Control System (Controller and Management System) : This is the "central nervous system" of the forklift. ANTMAC's full CAN bus intelligent control system can perform millisecond-level coordinated control of the dual motors and all electrical components of the vehicle (such as lights and instruments). Advanced AC inverter technology makes starting and acceleration incredibly smooth, keeps cargo as stable as a rock, and maximizes the utilization of electrical energy.

③ Battery (Energy Source) : The forklift's "energy stomach." ANTMAC primarily promotes lithium iron phosphate (LFP) batteries , whose thermal stability far surpasses that of ternary lithium batteries, offering extremely high safety. Our battery packs integrate an intelligent battery management system (BMS) that monitors the status of each cell in real time, achieving precise balancing, overcharge and over-discharge protection, and predicting battery health through data analysis, extending battery life by more than 30%.

ANTMAC's breakthrough : We integrate the three core electric systems (battery, motor, and controller) into a unified thermal management design. In high-temperature environments, an independent cooling system ensures that the motor and controller do not overheat and throttle; in low-temperature environments, the BMS actively heats the battery to maintain its activity. This guarantees consistent performance of the forklift under all weather conditions and operating conditions.

II. Skeleton and Joints: The Vehicle Body Structure Provides a Stable Foundation

A robust chassis is the foundation upon which all performance is built, and its design is directly related to durability, stability, and operator safety.

The mast system , the "arm" of the forklift, consists of the inner mast, outer mast, fork carriage, chain, and side rollers . ANTMAC employs a wide-view mast design and high-bending-strength steel sections to ensure excellent stability while maintaining a wide field of vision. This is achieved by ensuring that mast deformation is significantly lower than industry standards when fully loaded and lifted to maximum height.

Frame and drive axle : the forklift's "body and legs." We use a reinforced frame with box-section welding , and perform robotic welding and overall stress relief treatment at key stress points to eliminate the risk of cracking. The drive axle integrates a high-efficiency drive motor and wet brakes , providing smooth, maintenance-free braking, powerful drive force, and reliable braking.

ANTMAC's breakthrough : We laser harden the gantry roller tracks, doubling their hardness and significantly increasing their wear resistance; the chassis undergoes millions of fatigue tests and employs a dual anti-rust process (electrophoretic primer + polyurethane topcoat) to ensure long-term rust-free operation even in humid or corrosive environments.

III. Neural Networks: Intelligent and Human-Centered Interactive Interfaces

Modern electric forklifts are highly intelligent devices, and their "neural network" determines the user experience and maintenance efficiency.

Digital Instruments and Interactive Terminals : ANTMAC is equipped with a full-color LCD screen that clearly displays information such as speed, battery level, running time, and fault codes. Some models support optional smart terminals , enabling advanced functions such as electronic fences, access control management, and fleet dispatching.

Sensor network : Sensors distributed throughout the vehicle body (such as pressure, temperature, angle, and speed sensors) are the "eyes" and "ears" of the control system, collecting data in real time and providing a basis for intelligent control.

Ergonomic design : Although not a "part," it is the soul of the structure. ANTMAC's cockpit is based on ergonomic design, with adjustable seats, ergonomic handles, and a low-noise environment (<75 decibels), which greatly reduces operator fatigue and directly improves safety and efficiency during long-term operations.

ANTMAC's breakthrough : We offer a cloud-based remote monitoring and management system . Customers can use their computers or mobile phones to view the location, working status, and health reports of each forklift in their fleet in real time, and receive preventative maintenance reminders, achieving a leap from "recovery maintenance" to "predictive maintenance."

IV. From General Construction to ANTMAC Value: Choosing one is choosing a reliable system.

The significance of ANTMAC's general-purpose construction lies in establishing an evaluation benchmark. And every design and material selection in ANTMAC is multiplied in value based on this benchmark.

A large food and beverage company was selecting a system for its central warehouse. They disassembled and compared prototypes from several brands and found that ANTMAC stood out in several details: the motors used were custom models from well-known brands ; all electrical connectors met IP67 waterproof standards , far exceeding the norm; and the hydraulic lines used double-layered steel wire braided hoses with higher pressure resistance. It was precisely this solid use of materials in these "unseen" areas that ultimately led them to choose ANTMAC, resulting in near-zero unexpected downtime over the following three years.

Choosing an electric forklift is essentially choosing a productivity system comprised of thousands of precisely coupled parts . ANTMAC is committed to making each component a reliable, long-life module, and to using intelligent design to make them work together more efficiently.

We don't just sell forklifts; we offer a quality commitment that can withstand disassembly and verification , as well as a suite of intelligent tools to help businesses achieve digital and lean management . When you delve into its construction, you'll discover that ANTMAC's value is rooted in its unwavering commitment to quality and its deep cultivation of technology.

In the electronics manufacturing industry, there are stringent requirements for electrostatic discharge (ESD) control. ANTMAC offers a full-vehicle anti-static version for such customers , forming a complete ESD discharge path from specially formulated tires and anti-static paint to grounded masts and forks. This is not a simple addition of accessories, but a systematic engineering project carried out from the initial structural design to ensure absolute safety during operation in a cleanroom.

Dissecting the "Internal

Dissecting the "Internal

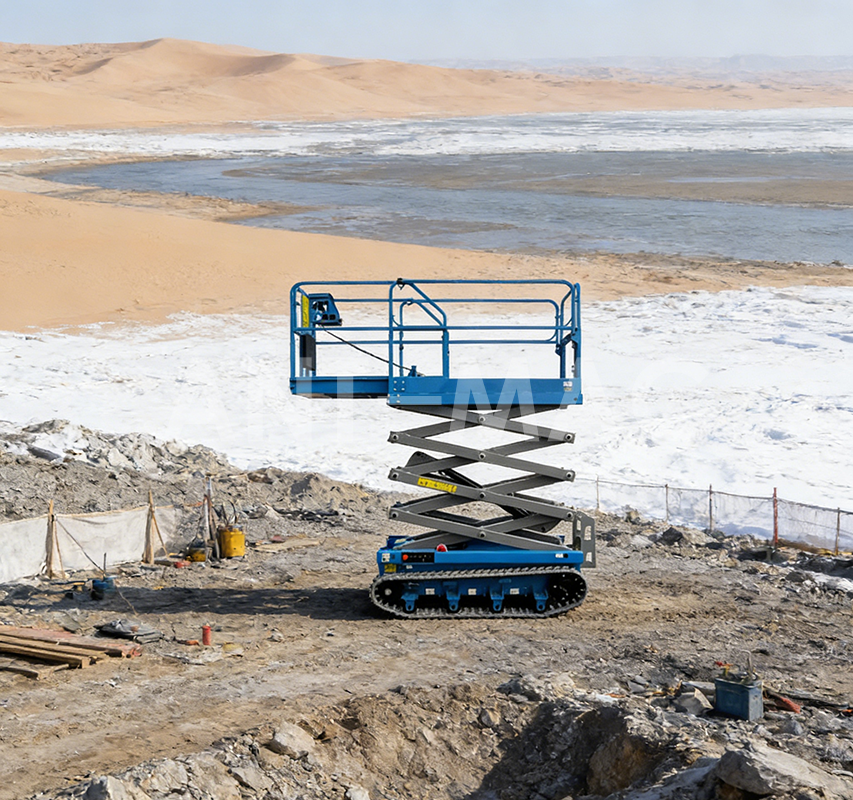

Foreseeing 2026: When Scissor

Foreseeing 2026: When Scissor

The Ultimate Balance Between E

The Ultimate Balance Between E

Engineering Decoding: The Art

Engineering Decoding: The Art

Russian

Russian