Immersive Scenario-Based Experience: Redefining Efficient Aerial Work

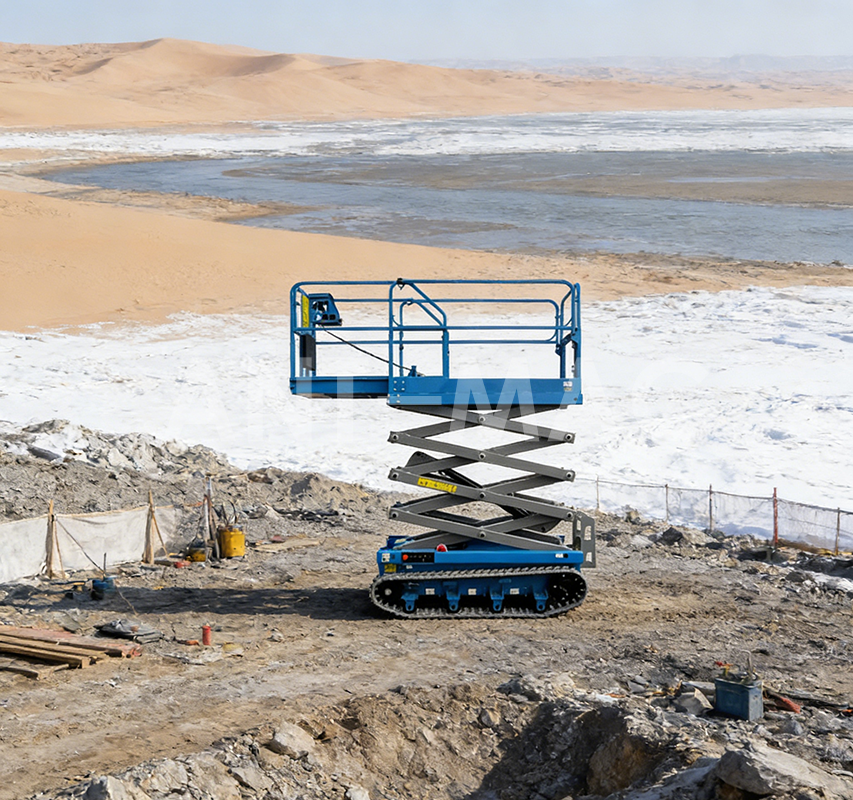

In the intelligent manufacturing facility of Ant Machinery in Jining, a procurement director from Pakistan is deeply engaged in testing a tracked scissor lift. Accompanied by our engineers, the director conducts comprehensive functionality tests—from basic operations to complex scenario simulations—to verify the equipment’s performance parameters and alignment with real-world operational needs.

Visualizing Product Strength: Multi-Dimensional Technical Advantages

1. Ergonomic control system

The ergonomic operating system integrates lifting, moving and platform extension functions. New operators can master basic operations within 5 minutes, greatly shortening the learning time.

2. Omnidirectional Maneuverability

Equipped with an all-directional drive system, the lift supports 360° in-situ rotation, enabling quick angle adjustments in tight spaces without repositioning. This feature boosts operational efficiency by up to 40% in confined environments.

3. Robust Safety Features

Standard safety configurations include dual overload protection and emergency stop cables, providing basic operational security. For enhanced stability, an optional intelligent leveling system automatically compensates for inclines up to 1.7°, with a safety margin 1.5 times the industry standard, as certified by international safety laboratories.

Customer Value Insight: From Product Experience to Solutions

Through end-to-end operational validation, we’ve witnessed the equipment’s systematic advantages in human-machine interaction, safety protection, and scenario adaptability," commented the technical director of the Pakistani client. "The combination of an extendable platform and compact body specifically addresses our space constraints and high-precision requirements in commercial complex projects.

Shandong Ant Construction Machinery provides tailored support for various industries, and reservations are now open. If you're ready to revolutionize your aerial work efficiency, let our innovative solutions enhance your operations.

Dissecting the "Internal

Dissecting the "Internal

Foreseeing 2026: When Scissor

Foreseeing 2026: When Scissor

The Ultimate Balance Between E

The Ultimate Balance Between E

Engineering Decoding: The Art

Engineering Decoding: The Art

Russian

Russian